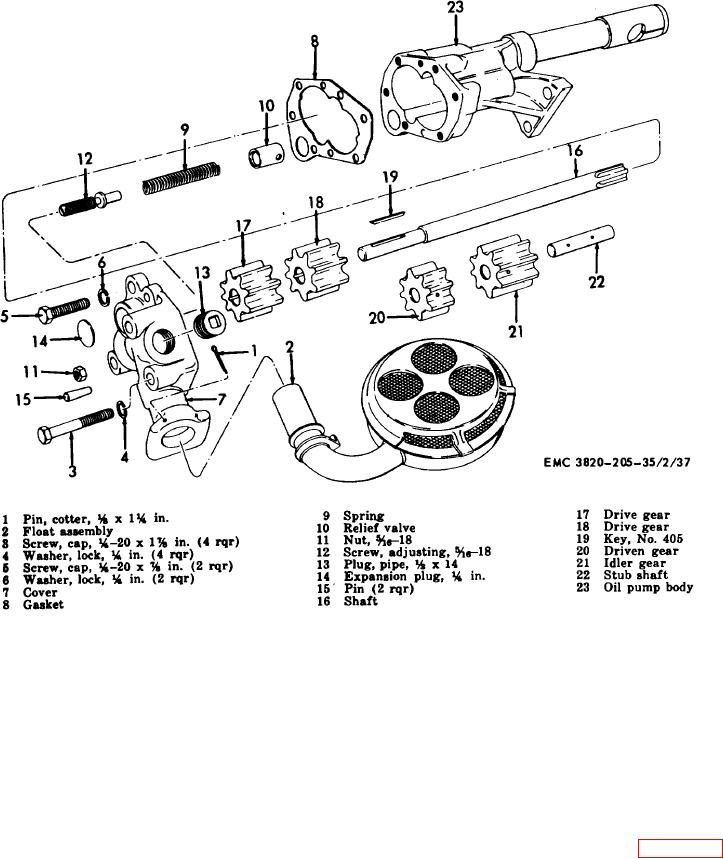

Figure 28. Engine oil pump assembly, exploded view.

should not contact the walls of the

(5)

Inspect the relief valve piston for

pump chamber.

freedom of motion and the valve

spring for proper pressure.

(2)

Inspect the cover and face of the

gears for excessive wear or. scoring.

(6)

The oil pressure may be adjusted by

With the gasket assembled to the

turning the adjustment screw. Engine

body, there should be 0.0015 to 0.006

oil pressure must be maintained

in. clearance between the gears and

between 55 and 65 psi.

the cover. Replace cover or gears if

95.

Engine Oil Pump Assembly Reassembly and

they are worn or scored.

Installation

(3)

Inspect the pump body for cracks or

Reassembly.

Refer to figure 28 and

a.

breaks. Replace a defective pump

reassemble the engine oil pump in the reverse order.

body.

Note. Install the key (19) and the

(4)

Inspect the drive shaft and shaft stud

gears (18 and 17) on the shaft (16)

for wear and scoring. Replace a

and install as an assembly in the

defective shaft.

body (23).

AGO 3456A

61