(2)

Install the engine oil pan (par. 91).

b.

Installation.

(3)

Install the engine housing (TM 5-

(1)

Refer to figure 27 and install the

3820-205-20/2).

engine oil pump assembly on the

engine.

(4)

Install the engine assembly (par. 30).

Section XVI. PISTON AND CONNECTING ROD ASSEMBLIES

(3)

Remove the cylinder head and valves

96.

General

The pistons used in this engine are made of an

(4)

Remove the oil pump assembly (par.

aluminum alloy. There are three compression rings and

two oil rings on each piston. A piston pin connects the

piston to the connecting rod. Each connecting rod and

(5)

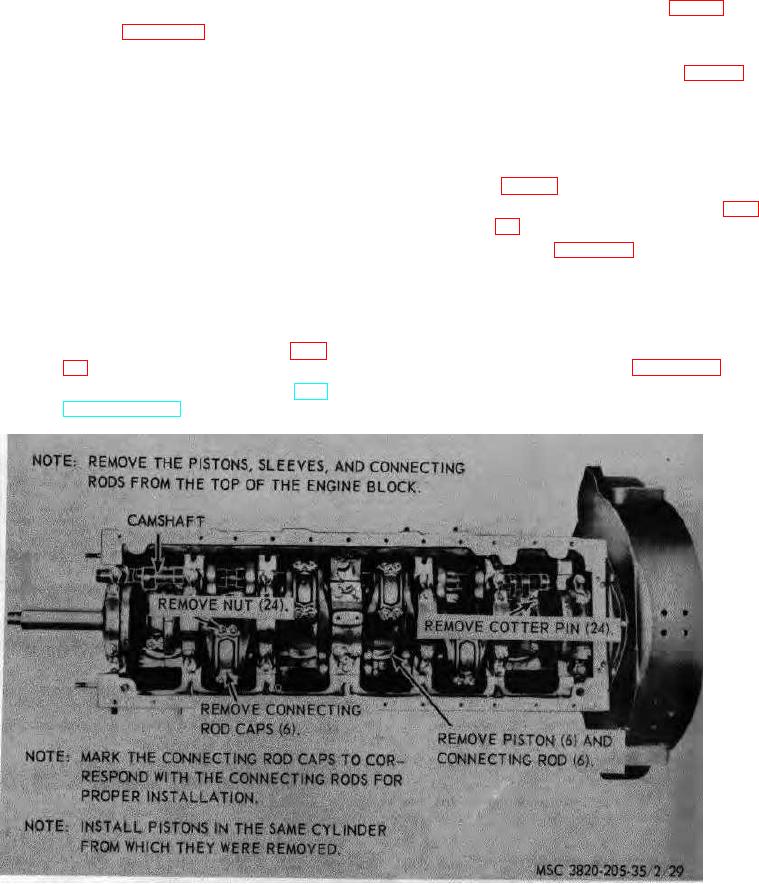

Refer to figure 29 and remove the

rod cap are matched and are not interchangeable.

piston and connecting rod assemblies

from the engine.

97.

Piston and Connecting

Rod

Assemblies

Removal and Disassembly

Note. Remove the ridge and carbon from the top of

the cylinder sleeve before removing the piston from

a.

Removal.

the engine block.

(1)

Remove the engine assembly (par.

Disassembly..

Refer to figure 30 and

b.

disassemble the piston and connecting rod assemblies.

(2)

Remove the engine housing (TM

Figure 29. Pistons, sleeves, and connecting rod assemblies, removal and installation.

AGO 3456A

62