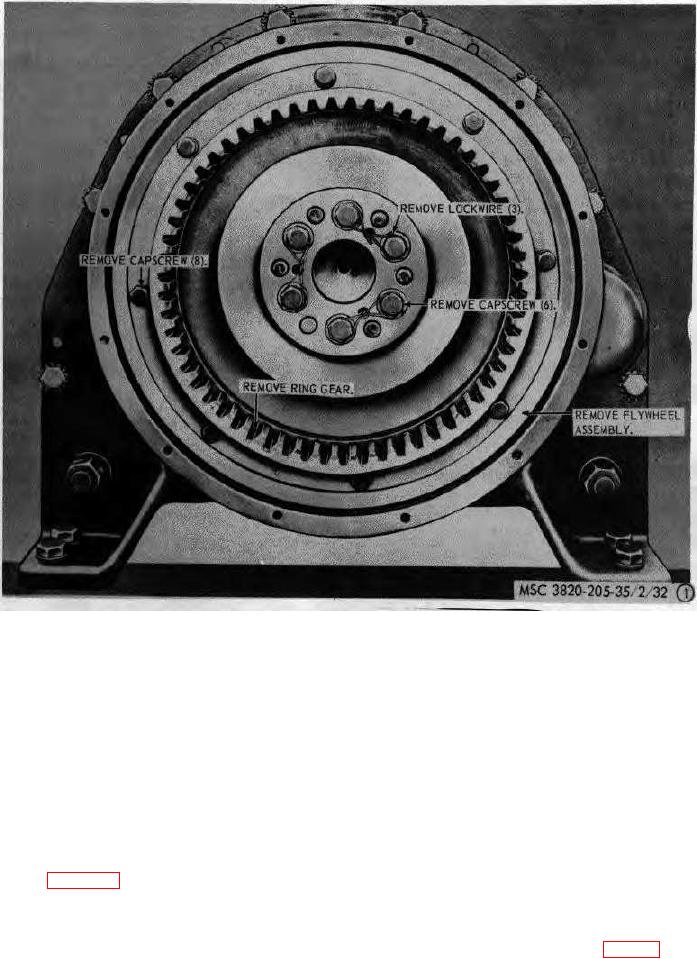

Figure 32. Flywheel and housing, removal and installation.

c. Mount an indicator on the flywheel housing and

(2) Inspect the flywheel housing for cracks,

breaks, elongated mounting holes, or other

inspect the flywheel for runout to be sure that the

damage.

Replace a damaged flywheel

crankshaft flange has not been sprung or damaged.

housing.

Inspect the counterbore in the flywheel for damage.

Maximum indicator reading must not exceed 0.008

(3) Inspect the ring gear for broken or worn

inches.

teeth. Replace a defective ring gear.

d. Mount the indicator on the face of the flywheel

107.

Flywheel and Housing Installation

and inspect the bore of the flywheel housing for runout.

Maximum reading should not exceed 0.008 inches.

a. Install the ring gear on the flywheel by heating

e. Using a suitable lifting device, remove the

the ring gear until it will slip over the flywheel.

blocking from the engine.

b. Refer to figure 32 and install the flywheel and

f. Install the engine rear panel (TM 5-3820-205-

housing on the engine.

20/2).

g. Install the clutch assembly (par. 89).

67