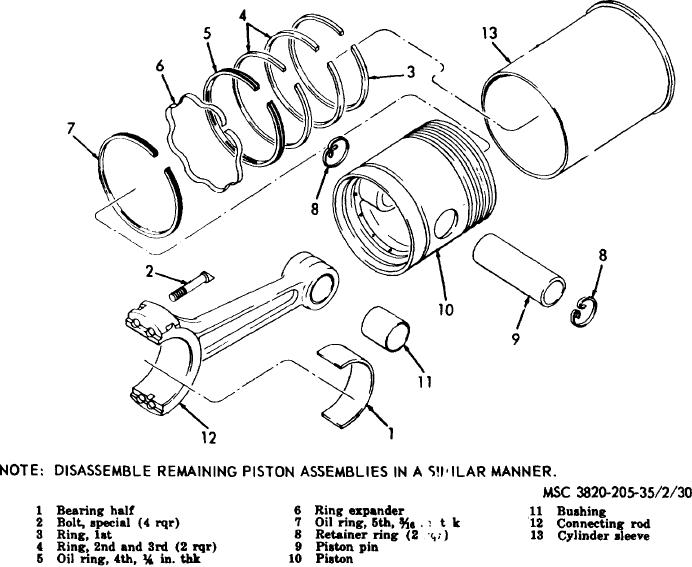

Figure 30. Piston, sleeve, and connecting rod assembly, exploded view.

the sleeve should require a 5 to 10

98.

Piston and Connecting Rod

Assemblies

pound force to pull two 0.004 in.

Cleaning, Inspection, and Repair

feeler gages from between the piston

Cleaning. Clean all parts with an approved

a.

and sleeve. Replace a piston that

cleaning solvent and blow dry with compressed air.

does not meet these standards.

b.

Inspection and Repair.

(4)

Measure the piston pin bore with an

inside micrometer.

The proper

(1)

Use a grooved cleaning tool and

diameter is 1.7498 to 1.7500 inch. If

clean the carbon and varnish out of

the piston pin bore is worn larger than

the ring grooves in the piston.

1.7502 in., replace the piston.

(2)

Clean the oil holes in the connecting

(5)

Roll each piston ring completely

rods and pistons with compressed air.

around in its respective groove in the

(3)

Inspect each piston for cracks,

piston. The fit must be free around

breaks, scoring or other damage.

the entire piston circumference. If the

Measure the cylinder sleeve bore with

rings are tight, they can be lapped

an inside micrometer. The proper

slightly with a very fine emery cloth

distance is 5.5625 to 5.5645 inches.

laid-on a flat surface using a light,

Place the piston in an inverted

uniform pressure.

position about two inches down in the

cylinder sleeve bore. The piston fit in

AGO 3456A

63