TM 5-3820-233-12/1

maintenance checks and services (para 3-2).

2-9. General

(2) Disengage engine and feeder clutch.

a. The instructions in this section are published for

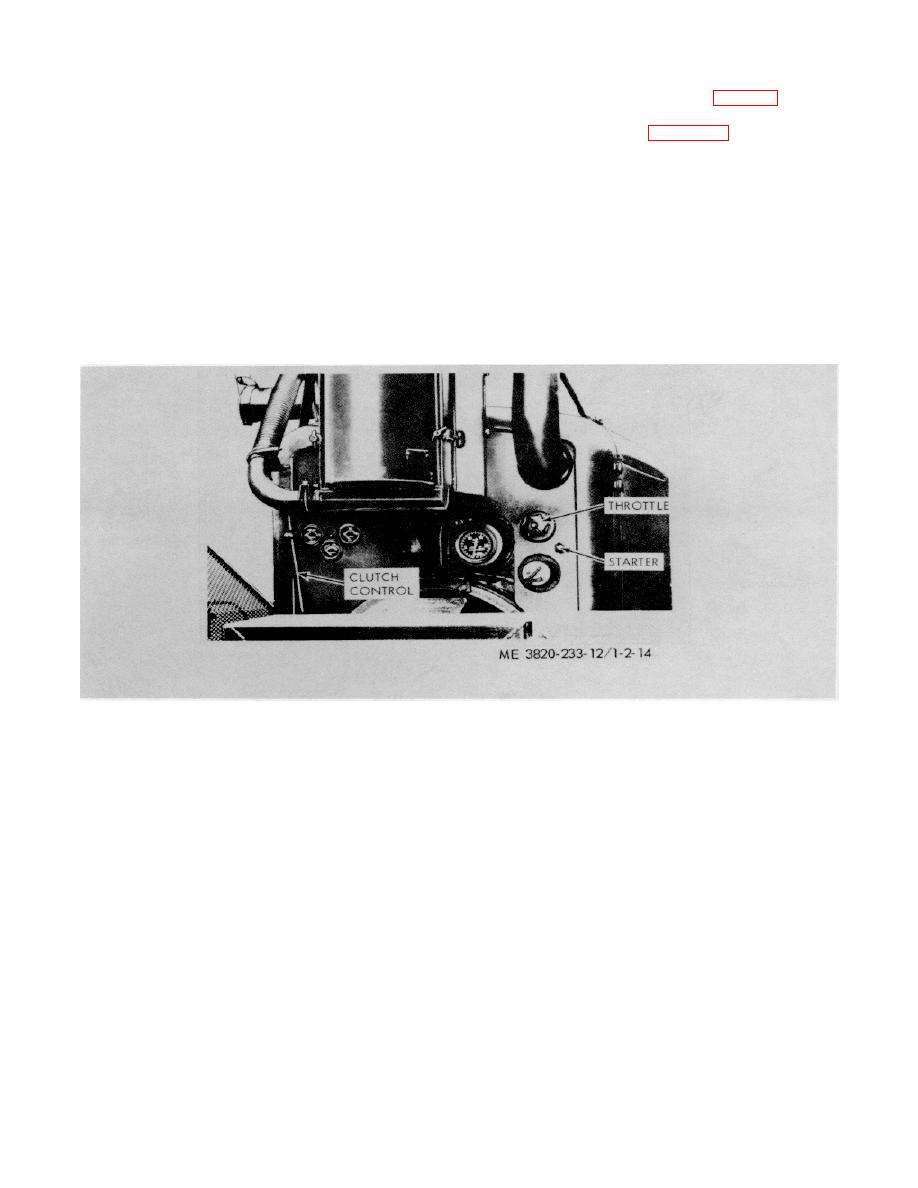

b. Starting. Refer to figure 2-14 and start the primary

the formation and guidance of the personnel re-

jaw cruasher as follows:

sponsible for operation of the primary jaw crusher plant.

(1) Disengage plant clutches.

b. The operator must know how to perform every

(2) Start engine and warm to operational

operation of which the jaw crusher is capable. This

temperature.

section gives instruction on starting and stopping the

(3) Partially engage clutch. Then quickly engage

basic motions of the jaw crusher, and on coordinating the

engine clutch. This can be done at engine or with clutch

basic motions to perform the specific tasks for which the

ever on walk-way platform.

equipment is designed. Since nearly every job presents

(4) Engage plant clutch for feeder.

a different problem, the operator may have to vary given

(5) Run plant empty a few minutes to allow for

procedures to fit the individual job.

lubrication distribution.

2-10. Starting

(6) Recommended speed setting is 1800 RPM

a. Preparation for Starting.

for normal operation.

(1) Perform the necessary daily preventive

Figure 2-14. Starting the jaw crusher.

2-17