TM 5-3820-233-12/1

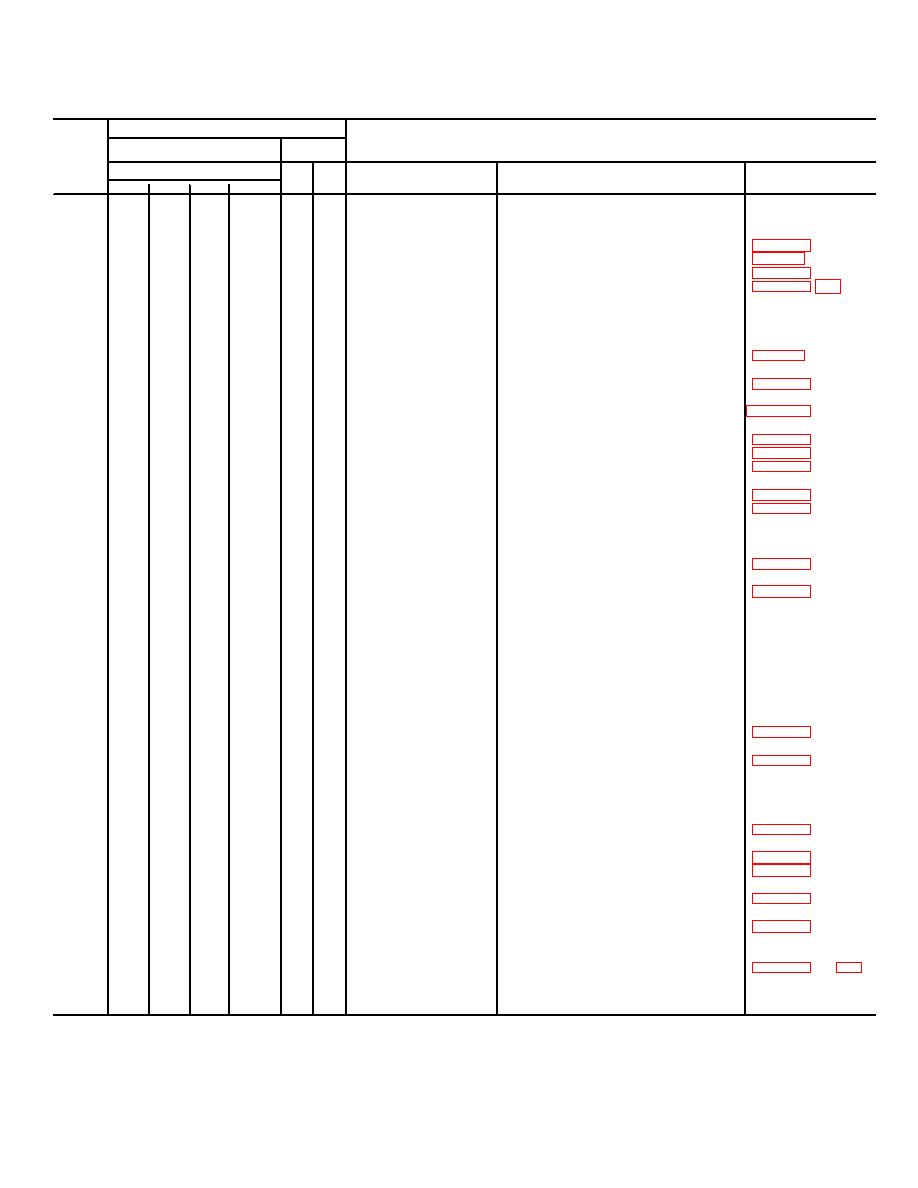

Table 3-1. Preventive Maintenance Checks and Services

Interval

B - Before operation

A - After Operation

M - Monthly

Operator

Org.

D - During Operation

W - Weekly

Q - Quarterly

Item

Daily

M

Q

Item to be inspected

Procedure

Reference

number

B

D

A

W

Lubricate in accordance

with current Lubrication Order.

1

X

Engine Oil

Check for proper oil level.

LO 5-3820-233-12/1

2

X

Generator and Fan Belts

Check for fraying and breaks.

3

X

Engine Coolant

Check for proper coolant leaks.

4

X

Engine Fuel Tank

Check fuel level.

5

X

Batteries

Check electrolyte level. In freezing

weather run engine for a minimum of

one hour after adding water. Check for

tightness of connections. Remove

corrosion.

6

X

Tires

Check for 65 psi tire pressure. Check for

cuts or damage.

7

X

Movable Jaw Wedge

Inspect and tighten the movable jaw

wedge.

8

X

Key Plate

Inspect for wear and replace if necessary.

Tighten if loose.

9

X

Jacks

Straighten and adjust if necessary.

10

X

Belt wiper

Check rubber flashing position.

11

X

V-Belt and Conveyor

Check and adjust tension.

Belt

12

X

Springs

Check tension of jaw crusher springs.

13

X

Tension Rod Threads

Check and lubricate.

and Pin

14

X

X

X

Mounting Hardware

Check tightness of bolts, nuts, capscrews

and all mounting hardware.

15

X

Toggle Plate

Inspect for excessive wear.

Instruments

16

X

1800 rpm recommended setting for

plant operating speed.

Idle - 1200 rpm

Maximum-2100 rpm

Oil Pressure-Normal

Idle - 30-60 psi

Operating speed-38-60 psi

Oil Pressure-Medium

Idle - 18 psi

for Safe Operation

Operating speed - 27 psi

Maximum rpm-30 psi

Operating speed - 160-185F.

Coolant Temperature

17

X

Engine Speed

Check and maintain recommended rpm.

Check periodically during operation.

18

X

X

Air Cleaner

Change filter element when red flag locks

at top of indicator.

19

X

Check for overheating.

20

X

Troughing and

Check all rolls to ensure they are rolling

Return Rolls

freely.

21

X

Conveyor

Check belt to be sure it is running

centrally.

22

X

Discharge Openings

Check for clogging or plugging.

23

X

Stationary Jaw

Check jaw for up and down movement.

To correct.

tighten key plates.

24

X

Reciprocating Feeder

Check clutch for slipping. Adjust if

Clutch

necessary.

25

X

Skirtboard Flashing

Check for spillage between flashing and

conveyor belt. Adjust flashing or replace

if necessary.

26

X

Lights

Ensure that all lights operate properly.

3-2