TM 5-3820-233-12/1

Section IV. TROUBLESHOOTING

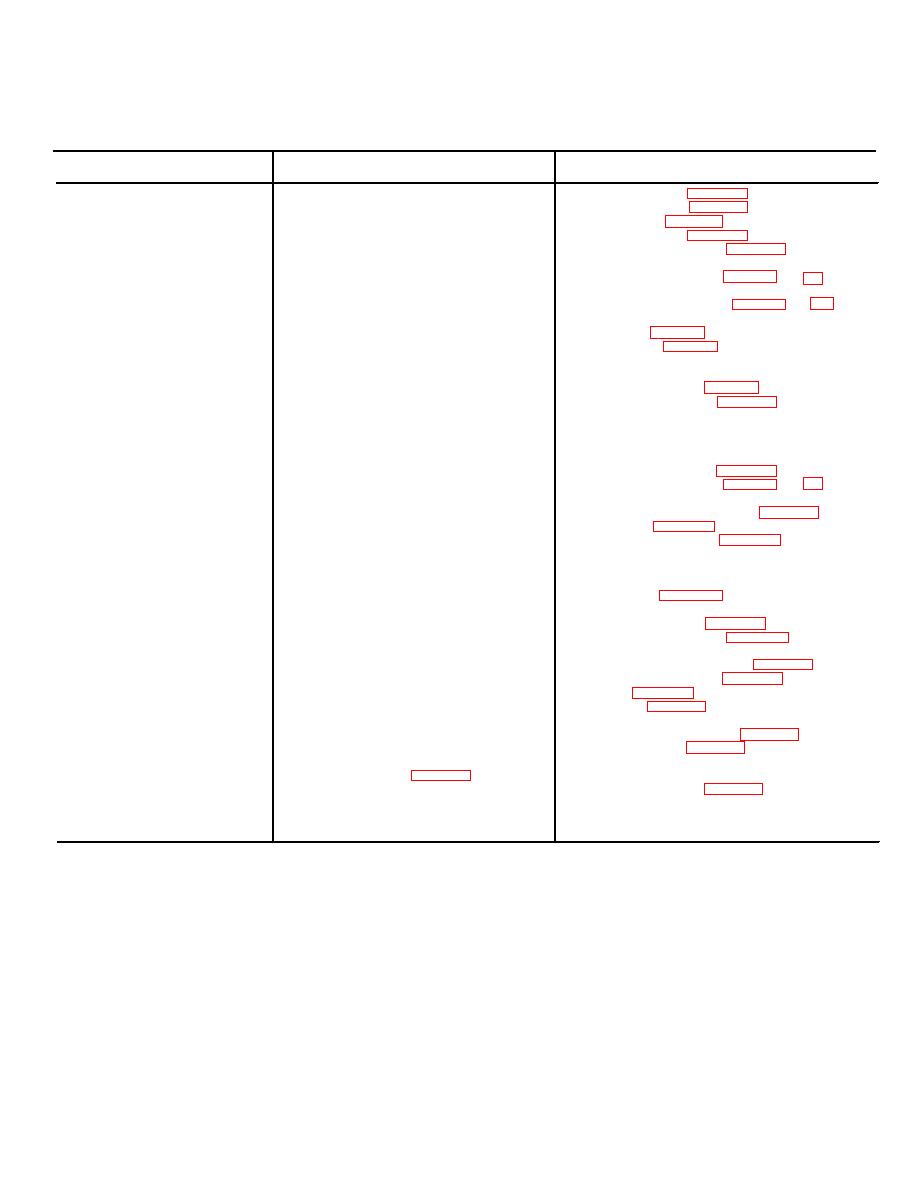

Table 3-2. Troubleshooting

Malfunction

Probable cause

Corrective action

1.

Starter Fails to Crank Engine.

a.

Battery-charge low,

a. Recharge batteries (para 3-11).

b.

Loose connection.

b. Tighten connection (para 3-11).

2.

Engine Fails to Start.

a.

Lack of fuel.

a. Refill fuel tank (para 3-13).

b.

Battery charge low.

b. Recharge batteries (para 3-11).

c.

Engine too cold.

c. Use primer to start engine (para 4-17).

d.

Air in fuel system.

d. Vent fuel system.

e.

Clogged fuel filter.

3.

Loss of Power

a.

Insufficient supply of fuel.

a. Check fuel system for clogged fuel lines or

b.

Air in fuel line.

b. Vent fuel system.

4.

Engine Overheats.

a.

Low on coolant.

a. Add coolant (Para 3-9).

b.

Radiator is clogged externally.

b. Clean out core (para 3-9).

5.

Engine Knocks Excessively.

a.

Lack of lubricating oil.

a. Check and fill crankcase to proper level.

(LO 5-3820-233-12/1).

b.

Engine overheating.

b. Check coolant system (para 3-9).

6.

Engine Smokes Excessively.

a.

Defective air cleaner.

a. Replace air cleaner filter (para 3-12).

b.

Improper grade of fuel.

h. Use correct fuel.

7.

Low or No lubricating Oil Pressure

a.

Crankcase oil level low.

a. Check and refill crankcase (LO 5-3820-233-

Indicated.

12/1).

b.

Defective oil pressure gage.

b. Replace oil pressure gage.

c.

Oil pressure low.

c. Inspect for clogged lines (para 4-23).

8. Low or No Fuel Pressure Indication. a.

Dirty or clogged fuel filter.

b.

Air in fuel system.

b. Vent fuel system.

9. Jaw Crusher Capacity Low.

a.

Loose stationary jaw.

a. Tighten key plates to tighten jaw (para 4-68).

b.

Speed incorrect.

b. Check speed (para 2-10).

c.

V-belt slippage.

c. Replace or adjust V-belts (para 4-56).

10. Overheated Bearings.

a.

Too much lubricant.

a. Remove excess lubricant.

b.

Insufficient lubricant.

b. Add lubricant in accordance with current

LO.

c. Speed too fast.

c. Reduce speed (para 2-10).

d. Plant not level.

d. Check level.

11. Excessive Jaw Wear.

a. Stationary jaw loose.

a. Tighten jaw key plates (para 4-68).

b. Discharge opening too small.

b. Correct discharge opening (para 4-71).

12. Excessive Feeder Plate Wear.

Improper loading.

Allow bed of material to remain on plate

to cushion impact of dumping load (para 4-61).

13.

Overfeed to Crusher.

Crank arm stroke incorrect.

Change feeder stroke length (para 4-61).

14.

Feeder Plate Fails to Operate.

Sheared shaft collar pin.

Replace pin (para 4-62).

15.

Feeder Plate Leaks Pit Fines.

Side plate lagging worn.

Adjust lagging (para 4-59).

16.

Belt Conveyor Running Off( Center

a. Troughing rolls not rotating.

a. Free troughing roll by removing stones.

of Troughing Rolls.

b. Troughing rolls need adjusting.

b. Adjust troughing roll position (para 4-51).

17. Conveyor Belt Slips on Head Pulley.

Belt not properly tightened.

Tighten conveyor belt (para 4-50).

18 . Spillage Along Conveyor Belt.

a. Conveyor belt too loose.

a. Tighten conveyor belt to eliminate sag

between troughing rolls (para 4-50).

b. Flashing positioned too far above

b. Adjust rubber flashing (para 4-52).

conveyor belt.

Section V. MAINTENANCE OF JAW CRUSHER PLANT

3-4. General

3-5. Secondary Fuel Filter Element

a. General. The fuel filter is located between the fuel

The instructions in this section are published for the

information and guidance of the operator to maintain the

pump and the fuel inlet manifold. It is important that the

jaw crusher plant.

fuel filter is kept clean at all times.

3-3