TM 5-3820-233-12/1

4-50. Belt Tension Adjustment

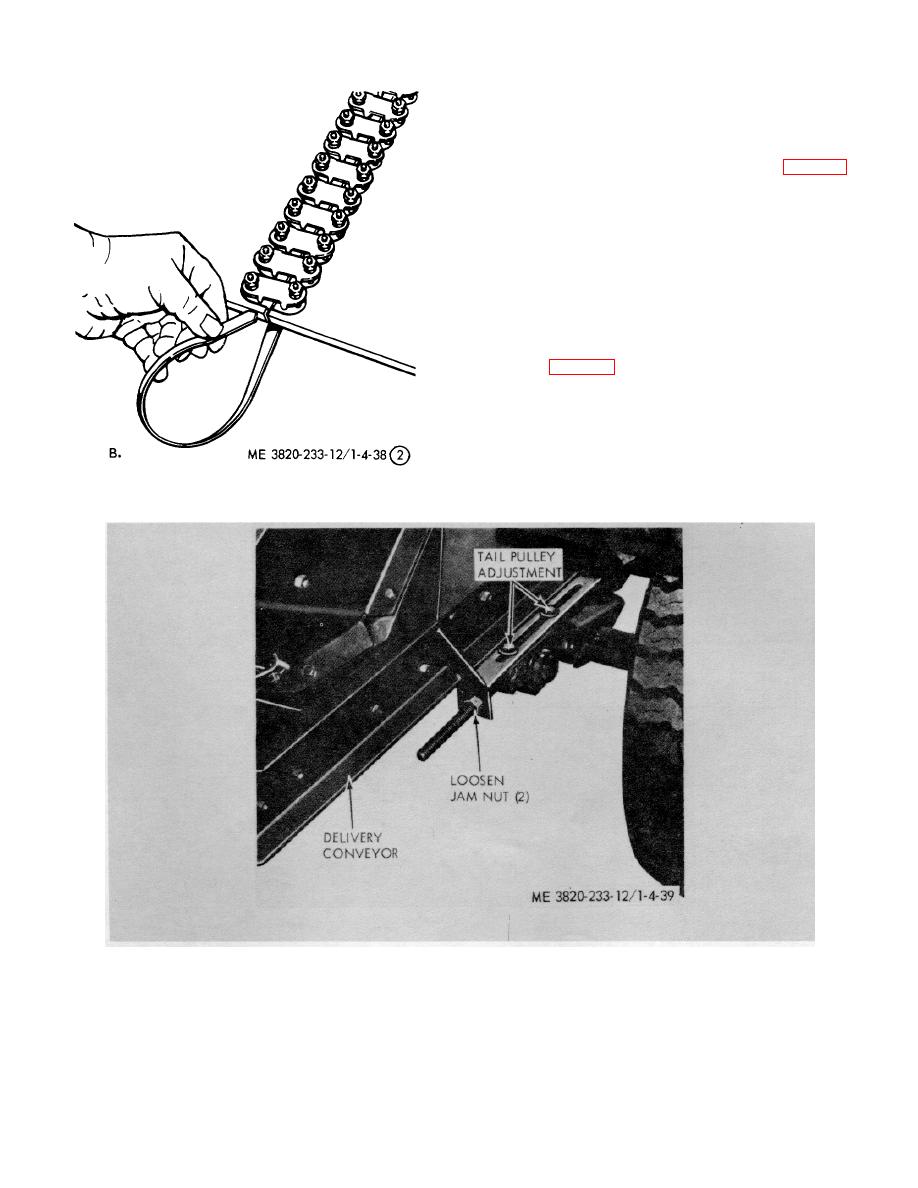

The conveyor is equipped with an adjustable tail pulley to

maintain the necessary belt tension.

a. Back off lock nuts on adjusting bolts and turn the

two adjusting nuts the same number of turns (fig. 4-39).

b. Tighten until proper belt tension is obtained to

prevent slippage and eliminate most of the belt sag

between troughing rolls. Belt sag should not exceed 1/2

to 3/4 inch between trough roll assemblies spaced on 4

foot centers (1% sag considered normal).

NOTE

When installed conveyor belt is to stand idle during seasonal

weather change, loosen belt to allow for contraction.

4-51. Belt Training

A slight adjustment of troughing and return rolls can

quickly correct belt travel over rolls and pulleys on the

conveyor (fig. 4-40).

a. Square the adjustable head pulley and tail pulley

with the frame.

b. Square troughing and return rolls.

c. Start the conveyor and run belt empty at reduced

speed. Check belt travel over rolls and head and tail

pulley and adjust troughing rolls where belt starts to run

Figure 4-38. Conveyor belt fastener installation

off center as follows:

(sheet 2 of 2).

Figure 4-39. Conveyor belt adjustment.

4-40