TM 5-3820-233-12/2

4-10. Replacement of Suppression Components

4-9. Inspection of Radio Interference Suppression

Refer to figure 4-1 to replace the radio interference

Components

suppression components.

a. Inspect the shielding cable and ground straps for

cuts, breaks, or damage.

b. Inspect internal external washers for breaks.

Section VIII. MAINTENANCE OF ROLL CRUSHER UNIT

4-11. Engine Fuel System

4-13. Fuel Injector

a. General. When improper fuel injection is suspected

Fuel for the engine fuel system comes from the fuel supply

tank, through the supply line, to the fuel strainer, to the fuel

of affecting the engine operation a systematic check should

pump. The fuel leaves the fuel pump under pressure and is

be made to determine the cause. The most likely cause is

forced through the fuel filter into the fuel manifold and

dirt or water in the fuel. Drain sediment from the diesel fuel

through fuel pipes to the fuel injectors. Surplus fuel returns

tank and drain the fuel filter housing. Replace filter

through outlet fuel pipes into the return manifold and back

to the fuel tank.

malfunctions check the fuel injectors as outlined below.

b. Priming the Fuel System.

4-12. Rocker Arm Cover

(1) If fuel flow is broken and air enters the fuel

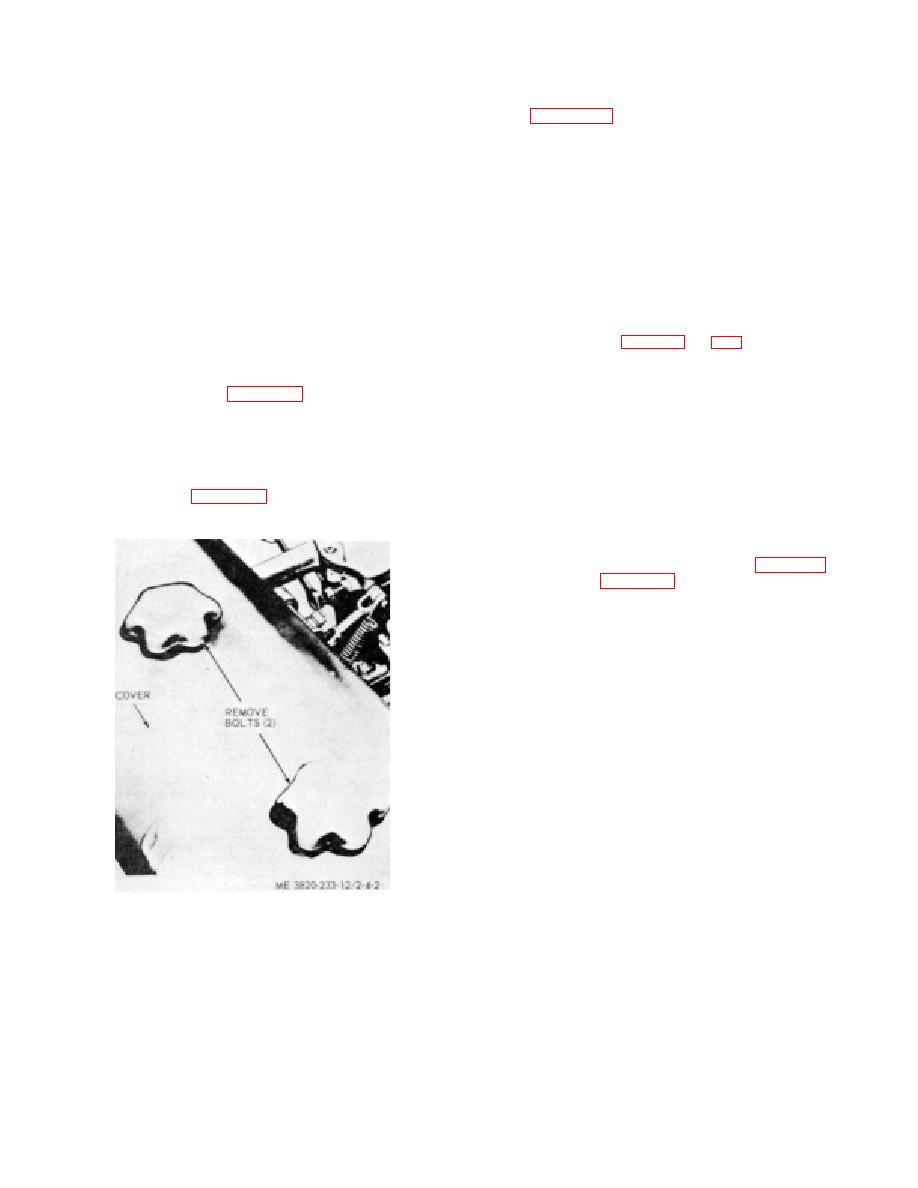

a. Removal. Refer to figure 4-2 and remove the rocker

system, the fuel system must be primed. Air in the fuel

arm cover.

system will cause hard starting or misfiring.

b. Inspection. Inspect the rocker arm cover for dents

(2) Run engine at a speed which produces

or cracks. Replace a defective rocker arm cover.

maximum miss or irregularity. Loosen fuel line sufficiently

c. Installation.

to "cut out" the cylinder. If one is found where loosening

(1) Clean gasket area and install a new gasket.

makes no difference in irregular engine operation or causes

(2) Refer to figure 4-2 and install the rocker arm

exhaust smoke to cease, probably, only that particular

cover.

injector is defective.

d. Removal.

(1) Remove the valve rocker cover (para 4-12).

(2) Refer to figure 4-3 and remove the fuel injector

as follows:

(a) Remove the fuel pipes from both the

injector and the fuel connectors.

(b) Install clean shipping caps on the injector

fuel inlet and outlet and on the fuel connectors.

(c) Remove rocker shaft bracket bolts and

swing rocker arms away from the injector.

(d) Remove injector clamp bolt, washer and

clamp.

(e) Loosen adjusting screws on injector

control rack lever and slide lever away from the injector.

(f) Lift injector from its seat in cylinder head.

(g) Cover injector hole in cylinder head to

keep foreign material out.

(h) Clean the exterior of the injector with fuel

oil and dry with compressed air.

Figure 4-2. Rocker arm cover, removal and installation.

4-5