TM 5-3820-233-35/2

CHAPTER 3

ENGINE REPAIR INSTRUCTIONS

Section I. ENGINE ACCESSORIES

29. General

This section contains those items which are considered

accessories to the engine. They consist of the starter,

battery-charging generator, radiator, water pump,

hydraulic governor, fuel pump, blower, blower drive, and

overspeed governor.

30. Starter

a.

General. The starter is a 24 volt, 4-brush,

gear drive type. The starter converts the electrical

energy, of the batteries into the mechanical energy

necessary to crank the engine. The tarter incorporates

an overrunning cloth which shifts the starting motor

pinion into mesh with the flywheel ring gear.

b.

Removal. Refer to Operator's manual.

c.

Bench Testing

Note

Never operate the cranking motor

more than 31 seconds at a time

MIN.

MAX.

MIN.

R.P.M.

without pausing to allow it to cool at

VOLTS AMPS

AMPS

R.P.M.

MAX.

least two minutes.

23.0

60*

90*

7000

10700

*INCLUDES SOLENOID

(1)

The armature should be checked for

freedom of operation by turning the

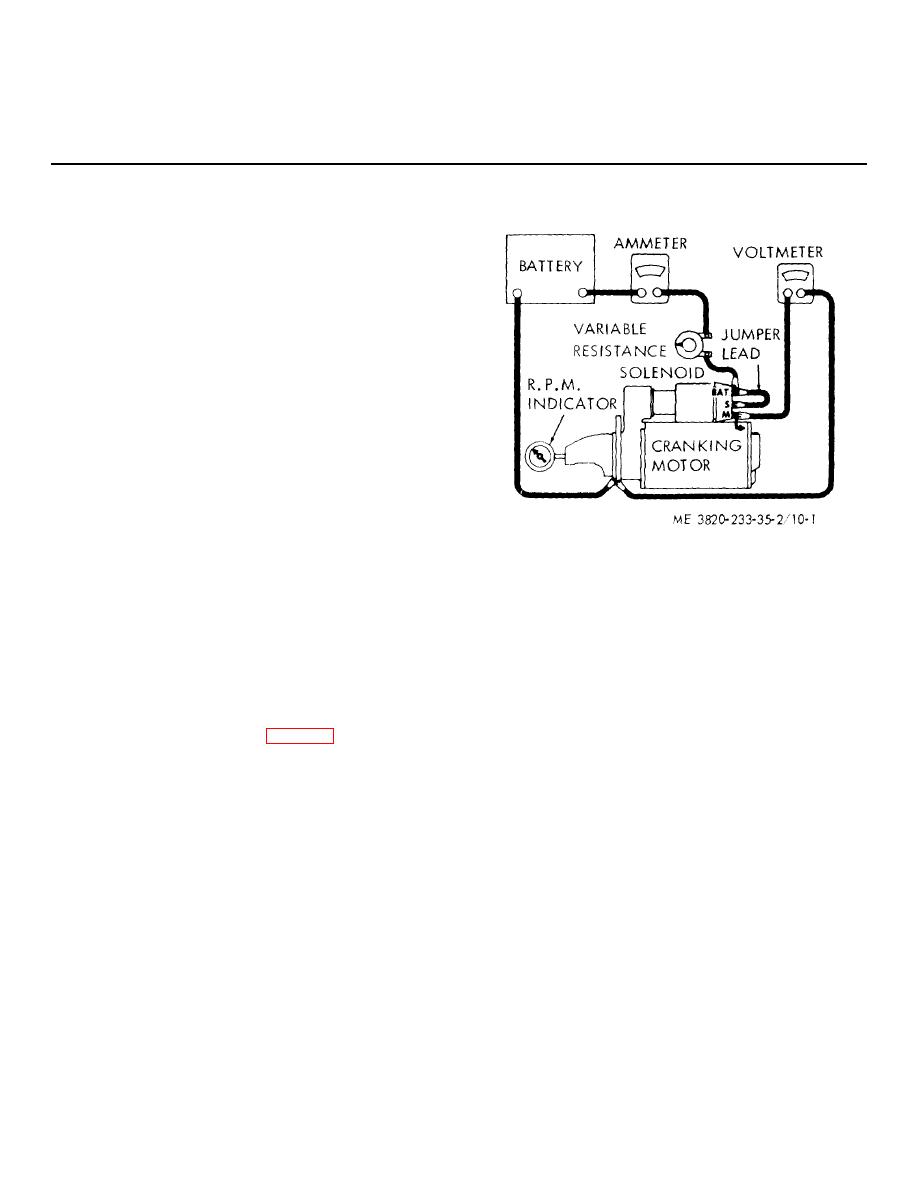

Figure 10-1. No load test.

drive. Tight, dirty, or worn bearings,

bent armature shaft, or loose pole

(b) Rated current draw and no-load

shoe screw will cause the armature to

speed indicates normal condition of the cranking motor.

drag and it will not turn freely.

(c)

Low free speed and high current

(2)

No-Load Test (fig. 10-1)

draw indicates: tight, dirty, or worn bearings, bent

armature shaft or loose pole shoes allowing armature to

(a) Connect the cranking motor in

drag, shorted armature, grounded armature or fields.

series with a fully charged battery to provide 24 volts, an

(d) Failure to operate with high

ammeter capable of reading several hundred amperes,

current draw indicates a direct ground in the terminal or

and a variable resistance. Also connect a voltmeter as

fields.

illustrated, from the motor terminal to the motor frame.

(e) Failure to operate with no

An rim indicator is necessary to measure armature

current draw indicates an open field circuit, broken brush

speed. Proper voltage can be obtained by varying the

springs, worn brushes, high insulation be-

resistance unit.

3-1