TM 5-3820-233-35/2

Figure 20-Continued

(2) Disassemble the cylinder head in the

numerical sequence as illustrated in fig. 22-2.

d. Cleaning, Inspection, and Repair

(1) Clean all parts with an approved cleaning

solvent and dry thoroughly.

(2) Inspect the cylinder head for cracks or

damage. Replace a cracked or damaged cylinder head.

(3) Check the bottom of the cylinder head for

warpage. The warpage limits are as follows:

Maximum longitudinal Warpage.

0.008 inch

Maximum Transverse Warpage.

0.004 inch

Replace the cylinder head if warpage is beyond the

limits specified.

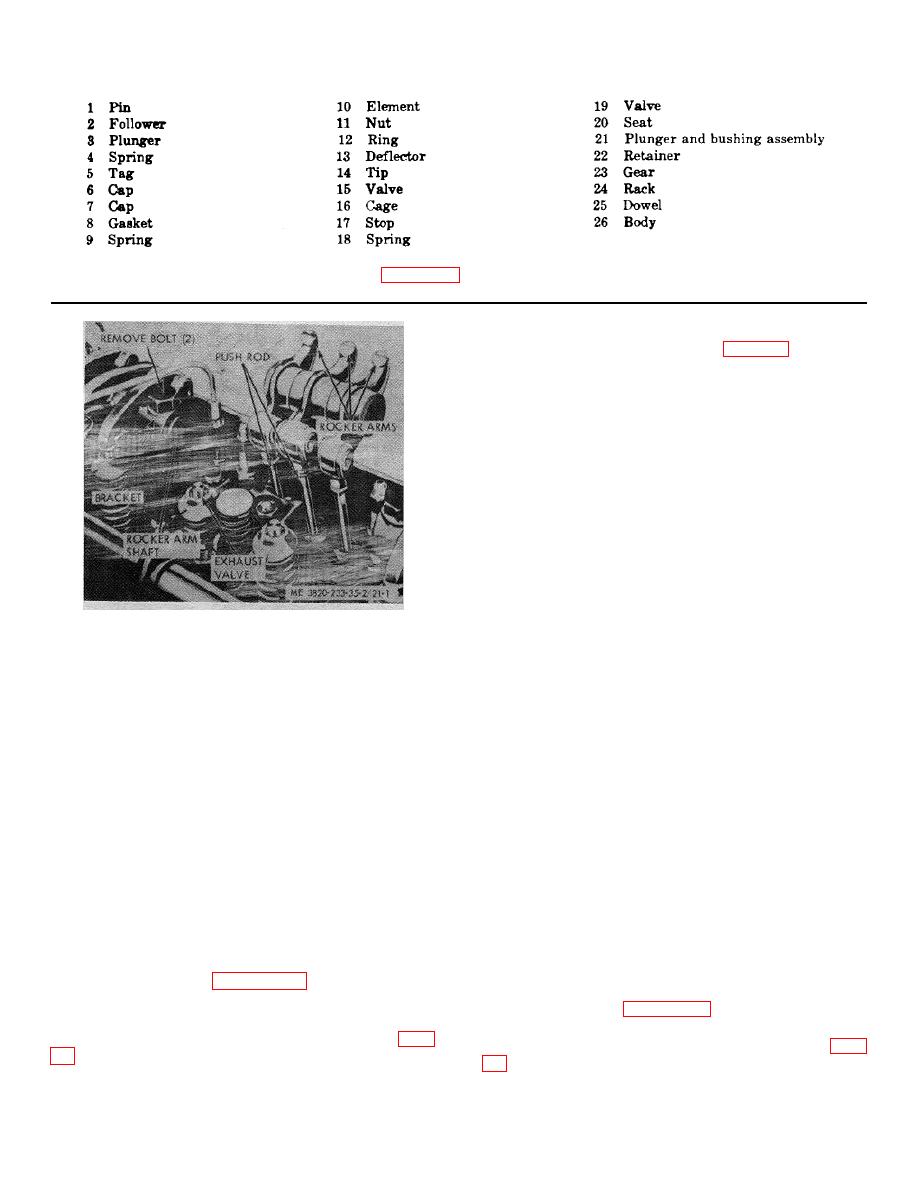

STEP 1. FOLD BACK ROCKER ARMS.

(4) Check the clearance between the valves

STEP 2. REMOVE ROCKER ARM SHAFT AND

and valve guides. Replace the guides if the clearance

BRACKETS.

exceeds 0.006 inch.

STEP 3. DISCONNECT PUSH ROD FROM ROCKER

(5) Inspect valve seats and injector tubes for

ARMS.

signs of over heating, looseness, excessive wear or

STEP 4. REMOVE ROCKER ARMS

other damage. Replace defective parts.

(6) Inspect the valves for cupped, pitted,

Figure 21-1. Rocker arms and shaft, removal and

burned or worn conditions. Grind the valves and reseat

installation.

the inserts to an angle of 30 degrees. Replace parts as

necessary.

(8) Remove the fuel oil filter (Operator's

(7) Inspect the valve springs for excessive

Manual).

wear and replace as necessary.

(9) Disconnect the governor fuel rod from the

(8) Inspect the cylinder head surface for

injector control tube lever. Remove the governor

pitting, scratches, or other damage. Resurface the head

subcap and fuel rod (Operator's Manual).

or replace as necessary.

(10) Remove the fuel injectors and injector

e. Reassembly

control tube (Operator's Manual).

(1) Reassemble the cylinder head in the

(11) Remove the instrument panel and throttle

reverse numerical sequence as illustrated on figure 22-

control rods (Operator's Manual).

2.

(12) Refer to figure 22-1 and remove the

(2) Follow the cylinder head tightening

cylinder head.

sequence shown on figure 22-3. Torque head bolts to

c. Disassembly

175-185-ft. lb.

(1) Remove the rocker arms and shafts (para

(3) Install the rocker arms and shafts (para

3-27