TM 5-3820-233-35/2

Section Ill. ROCK AND SAND CONVEYOR DRIVES

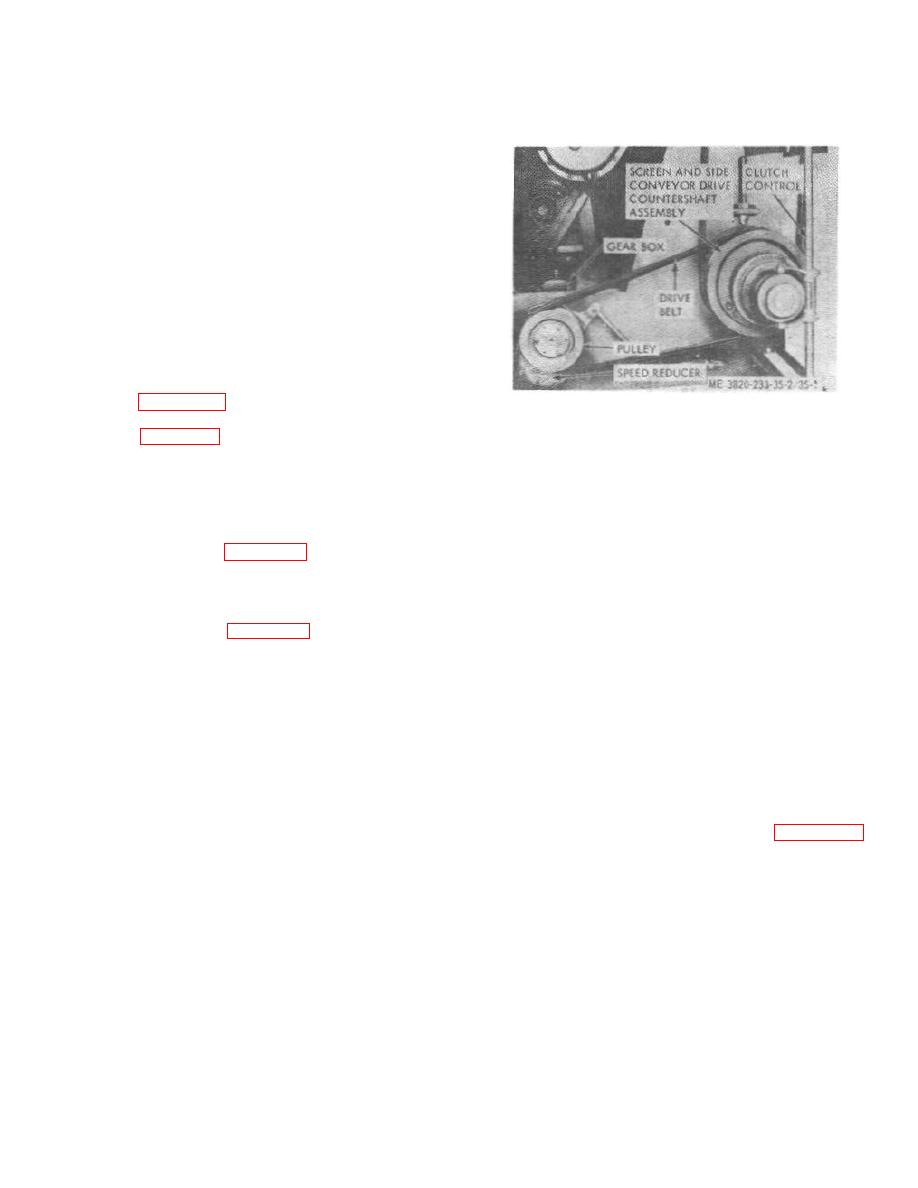

58. General

The rock and sand conveyor drive components are

similar in construction and maintenance procedures. A

gear box, countershaft, and speed reducer are the major

components in the drive assembly. The rock and sand

conveyor drive assemblies are belt driven and

controlled by twin disc clutch assemblies located on both

ends of the screen and side conveyor countershaft.

59. Sand Conveyor Drive

a. Removal and Disassembly

(1) Remove the main countershaft-t lower

countershaft guard, and the lower countershaft-to-sand

conveyor drive guard.

(2) The sand conveyor drive is shown

installed on figure 35-1. Remove and disassemble the

Figure 35-1. Sand conveyor drive, removal and

sand conveyor drive in the numerical sequence as

institution.

illustrated on figure 35-2.

b. Speed Reducer Disassembly

(5) Perform a magnetic inspection of all

(1) Drain lubricant from speed reducer.

gears and shafts. Inspect gear teeth for wear, pitting,

chipping, nicks, cracks, or scoring. Replace defective

(2) Disassemble speed reducer in the

parts.

numerical sequence as illustrated on figure 35-3.

(6) Inspect shafts for wear or bent condition.

c. Bearing Disassembly. Disassemble the bearing

Inspect splined shafts for twisted splines. Replace a

assembly as illustrated on figure 35-4.

defective shaft.

d. Gear Box Disassembly

(7) Inspect the speed reducer output hub for

(1) Drain lubricant from gear box.

wear, burrs, or nicks. Replace a defective hub.

(2) Disassemble gear box in the numerical

(8) Inspect all housings and covers to see

sequence as illustrated on figure 35-5. Insert or remove

that mating surfaces, and housing bores are free from

shims (8A, 8B, and 8C) or (24A, 24B, 24C) until a slight

nicks or burrs. Inspect for cracks or breaks. Repair or

clearance of .006 to .008 inch is obtained between gear

replace defective parts.

and pinion. Clearance can be determined by holding

(9) Replace all gaskets.

one shaft and rotating the other shaft.

(10) Thoroughly inspect all parts for wear or

Note

damage. Replace defective parts as necessary.

Install grease seals so knife edge of

seals counting the revolving shaft

and coupling is turned in toward

f. Gear Box Reassembly.

cater of gear box.

e. Cleaning, Inspection, and Repair

(1) Reassemble gear box in the reverse of

(1) Clean all parts in an approved cleaning

the numerical sequence as illustrated on figure 35-5.

solvent and dry thoroughly.

Insert or remove shims (8A, 8B, and 8C) or (24A, 24B,

and 24C) until a slight clearance of .006 to .008 inch is

(2) Inspect the coupling chain for broken

obtained between gear and pinion. Clearance can be

links. Replace damaged links as necessary.

determined by holding one shaft and rotating the other

(3) Inspect all oil seals for burrs or nicks.

shaft.

Replace a defective seal.

(4) Inspect all bearings for wear, scoring, or

pitting.

Replace

a

defective

bearing.

4-8