TM 5-3820-233-35/2

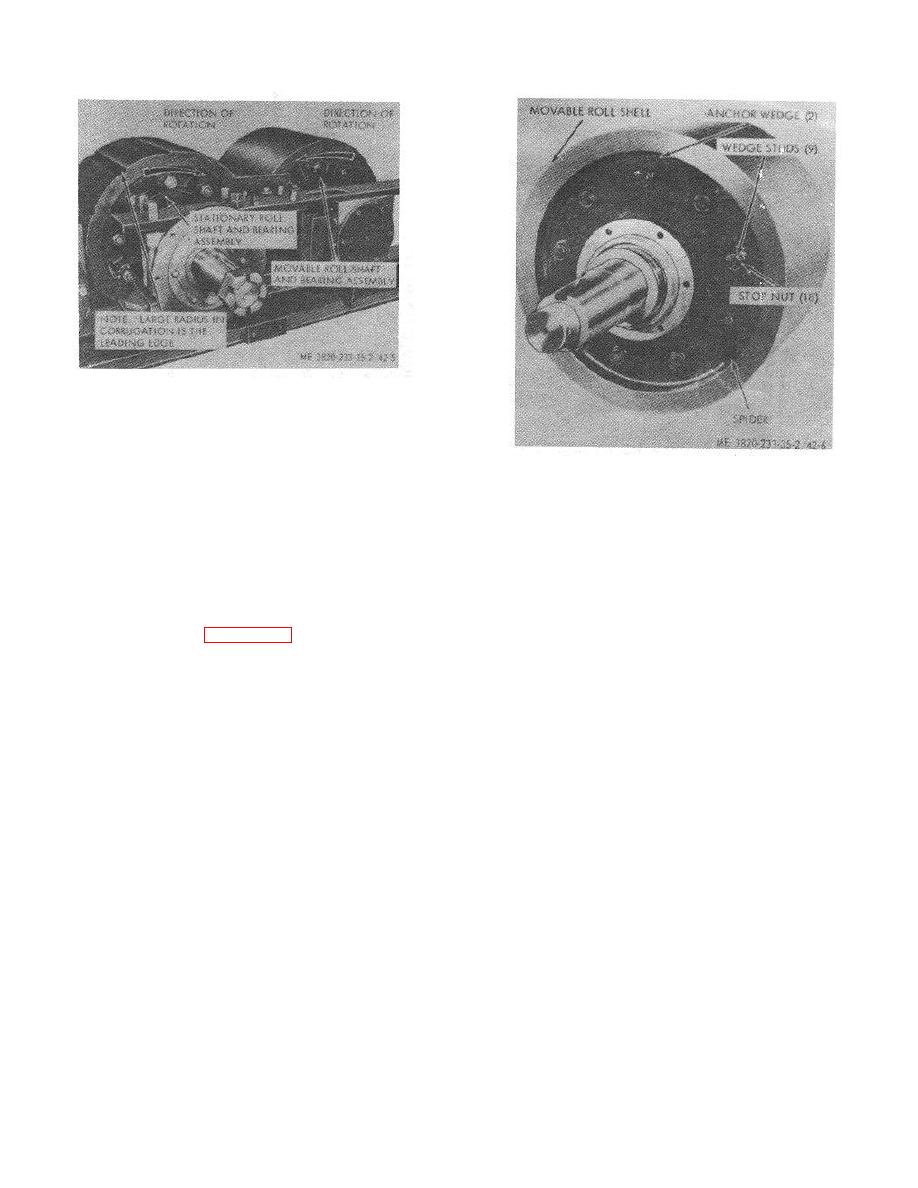

Figure 42-5. Movable and stationary roll shaft and

bearing assembly, removal and installation.

housing they are located (i.e.-pinion side, flywheel side).

Remove locking wire (235), capscrews (236), and

Figure 42-6. Anchor wedge, removal and

bearing adapter (237).

installation.

Note

Before

removing

the

bearing

j. Cleaning, Inspection. and Repair.

adapters (237 and 251) note the

(1) Clean all parts with an approved

location of the match mark on the

cleaning solvent and dry thoroughly.

outer surface of the bearing adapter

(2) Perform a magnetic inspection of all

in relation to the hole in the

gears and shafts. Inspect gear teeth for wear, pitting,

countershaft housing (fig. 429).

chipping, nicks, cracks, or scoring. Replace defective

(9) Refer to figure 42-1 and remove slinger

parts.

(240) and oil seal (241) from flywheel side of crusher.

(3) Inspect all shafts for wear or bent

(10) Remove locking wire (242), capscrews

conditions. Replace a defective shaft. If a new shaft is

(243), and countershaft cap (244).

to be press fit into a spider, the spider bores must be

(11) Remove the countershaft from the

welded and rebored to ensure a proper fit.

flywheel side of crusher.

(4) Inspect all bearings, bearing cones, and

Note.

bearing cups for wear, chipping, or nicks. Replace a

DO NOT attempt to remove the

defective bearing.

countershaft from the pinion gear

Note

side of crusher.

Do not replace a bearing cone or cup

(12) Remove bearing sleeve (238) and bearing

individually without replacing the

spacer (239) from countershaft (252).

mating cup or cone.

(13) Remove lock nut (245), lockwasher (246),

(5) Inspect bearing adapter bores. If the

bearing (247), and bearing sleeve (248) from

bores are 0.003 inch oversize in diameter, the bearing

countershaft.

adapters must be replaced.

(14) Insert a suitable pusher tool into flywheel

(6) Inspect housing, bearing blocks, and

end of countershaft housing and drive bearing (234)

bearing caps to see that mating surfaces, bearing bores,

from housing.

etc., are free from nicks or burrs. Inspect for cracks or

(15) Remove locking wire (249), capscrews

breaks. Repair or replace defective parts.

(250), and bearing adapter (251).

(16) Remove level plug (253) and fill plug

(254) from countershaft housing.

4-47