TM 5-3820-233-35/2

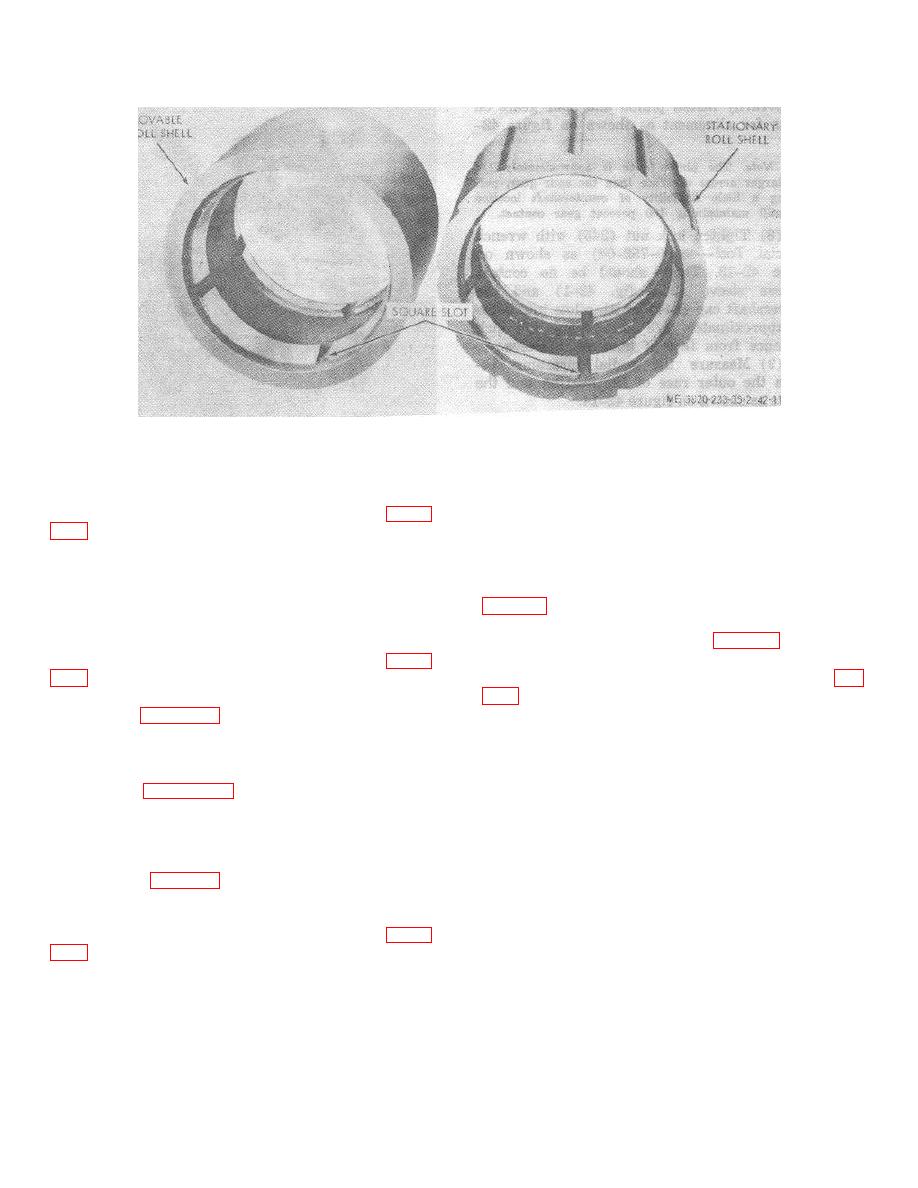

Figure 42-11. Roll shells.

Note

(2) Install the stationary roll shaft and bearing

Compress tension roll springs evenly

assembly to the crusher in the position shown on figure

until an approximately 1/2 inch gap is

obtained between coils.

(3) Aline the stationary roll shaft and bearing

assembly to the crusher frame by installing studs (256)

o. Countershaft Bearing Reassembly.

and nuts (255) (fig. 421).

(1) Assemble bearing adapters (237 and 251,

(4) Assemble the bearing block spacers (121)

next to the stationary bearing blocks (272 and 292).

marks on the adapters with those on the countershaft

housing made during disassembly (fig. 42-9).

(5) Install the movable roll shaft and bearing

assembly to the crusher in the position shown on figure

(2) Secure the bearing adapters to the

countershaft housing with capscrews (237 and 250, fig.

(6) Assemble parts 110 through 120 as

illustrated on figure 42-1.

(3) Install countershaft (252) int o housing.

Install bearing spacer (239), bearing sleeve (238),

n. Tension Roll Spring and Shear Washer

bearing (234), lockwasher (233), and lock nut (232) on

Reassembly.

the countershaft. Do not tighten lock nut (232).

(1) Reverse the disassembly procedure

(4) Center the flywheel end of shaft in

discussed on figure 42-3. Do not tighten the spring

bearing adapter using a clean block of wood or

adjusting bolt.

(2) Adjust the roll crusher discharge opening.

(5) Drive bearing (234) into housing until

The crusher discharge opening is the distance between

outer race of bearing shoulders against locating "stop" in

the two roll shell faces. Add or remove shims (116

bore of housing.

through 120, fig. 42-1) as required to close crusher

(6) Install bearing and sleeve assembly (245,

opening 1/8 to 1/4 inch less than the finished product

246, 147 and 248) onto flywheel end of countershaft.

size required.

Do not tighten lock nut (245) at this time.

(3) Turn spring adjusting bolt shown on figure

inch exists between the tension spring coils.

4-51