TM 5-3820-233-35/2

(13)

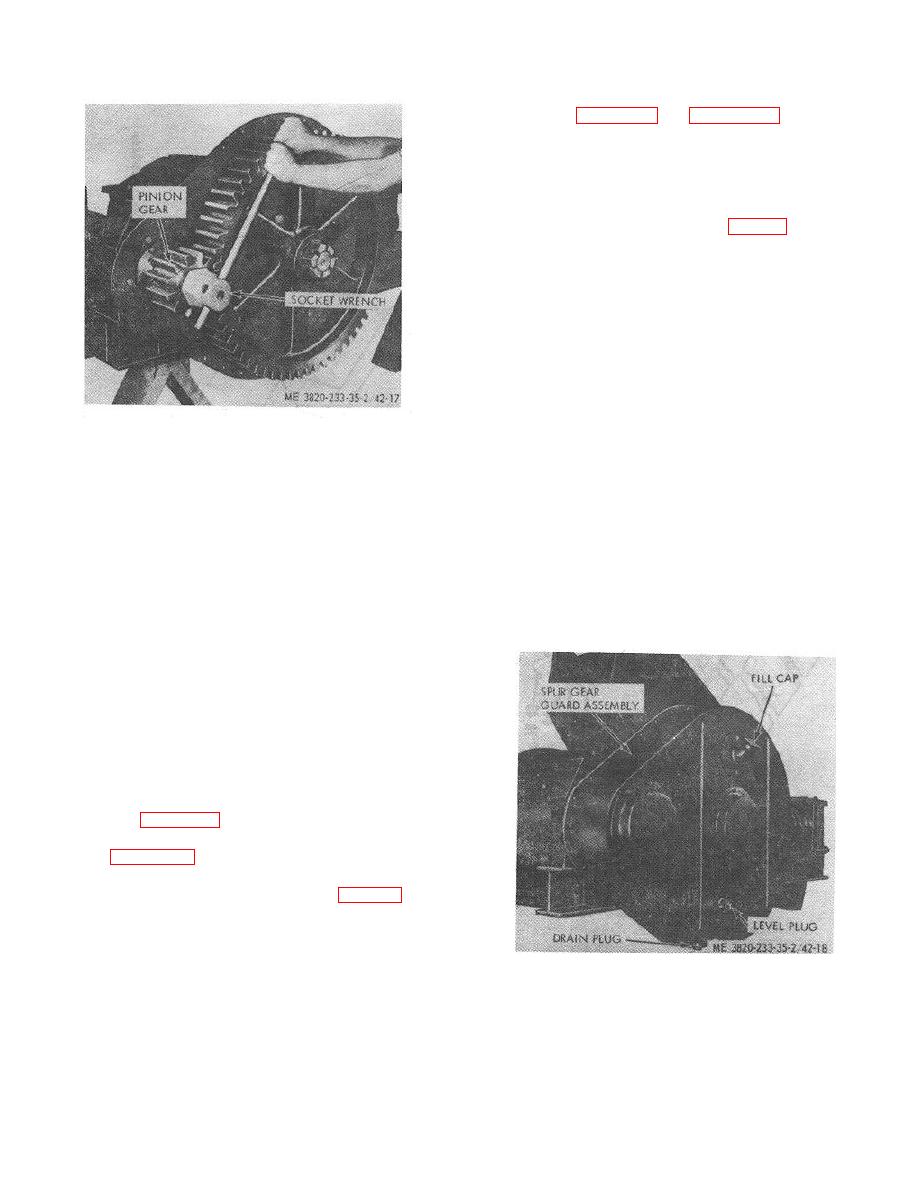

Reassemble parts 11 through 26 as

illustrated on figure 42-1. See figure 42-18 for installed

spur gear guard assembly.

s. Installation.

(1) Fill the finger gear guard assembly, spur

gear guard assembly, and countershaft housing with

lubricant (Operator's Manual).

(2) Install the roll crusher (para 26).

Figure 42-17. Tightening pinion on countershaft.

Section IX. UNDERCRUSHER CONVEYOR

73. General

(4) Inspect skirtboards and flashing for

damage and replace if necessary.

The undercrusher conveyor is located below the roll

(5) Inspect trough and return roll assemblies

crusher.

The undercrusher conveyor receives the

to make sure they turn freely. Replace defective

reduced aggregate from the roll crusher and delivers it

component parts as required.

to the elevating wheel, which carries the material to the

overhead conveyor.

74. Undercrusher Conveyor

a. Removal and Disassembly

(1) Remove the conveyor belt (Operator's

Manual).

(2) Remove

and

disassemble

the

undercrusher conveyor in the numerical sequence as

illustrated on figure 43-1.

b. Head and Tail Pulley Bearing Disassembly.

Refer to figure 43-2 and disassemble the pulley bearing

assembly.

d. Cleaning, Inspection, and Repair

(1) Clean all parts in an approved cleaning

solvent and dry thoroughly.

(2) Inspect pulleys for dents, cracks, and

Figure 42-18. Spur gear guard assembly.

other damage. Replace a damaged pulley.

(3) Inspect bearings for scoring, pitting, and

binding. Replace a defective bearing.

4-55