TM 5-3820-233-35/2

(6) Secure bearing cap (191) to the bearing

block (185) with capscrews (183) and oiler screw (181).

Push this partial assembly towards the hub of the spider.

Note

The movable and stationary roll

(7) Heat bearing cones (186 and 187) for

approximately 20 minutes in oil at 279 .

F

shaft

bearing

assemblies

are

disassembled and assembled in the

(8) Install bearing cone (187) onto shaft and

same manner.

The movable roll

into bearing block with the large outside diameter

towards end of shaft. Slide bearing cone firmly against

shaft

bearing

reassembly

is

bearing ring (189).

discussed in the following steps.

(9) Install the other bearing cone (186) onto

shaft and into bearing housing with the small outside

(1) Install oil seal (190) into bearing cap

diameter towards end of shaft.

(191). Be sure knife edge of seal is turned towards the

spider.

(10) Install and slide bearing cup (179) firmly

against bearing cone (186).

(2) Install the assembled oil seal and be aring

cap onto the shaft.

(11) Install bearing cap (174). Install three

capscrews (173) equally spaced around bearing cap.

(3) Install bearing ring (189) into position

Tighten capscrews until bearing cup (179) makes a

against the "step-up" on the shaft with the outer beveled

positive fit against bearing cone (186).

edge toward end of shaft.

(12) Check the clearance between bearing

(4) Assemble bearing cup (188) into bearing

block and bearing cap with a feeler, gauge to determine

block (185).

the shim thickness required.

(5) Install the bearing block (185) with

(13) Remove the bearing cap (174).

assembled cup (188) onto the shaft.

(14) Select a combination of shims to total the

determined thickness (step 11). Add 0.005 inch to 0.007

inch additional shims (176, 177 and 178).

Note

The correct amount of shim

thickness will be indicated when a

slight up and down movement

occurs while raising and lowering

the bearing block.

(15) Assemble oil seal (175) into bearing cap

(174) with the knife edge of seal towards the bearings.

(16) Assemble the bearing cap (174) and oil

seal (175) assembly to bearing block (185) with

capscrews (173). Install lock wire (172) through holes in

heads of capscrews (173).

(17) Assemble

the

remaining

bearing

assembly (192 through 214) in the similar manner

previously discussed (steps 1 through 16).

(18) The assembly of the movable and

stationary roll shaft and bearing assemblies, complete

with roll shells, to the crusher will be discussed in the

following instructions.

m. Slide Bar Reassembly.

(1) Install new slide bars.

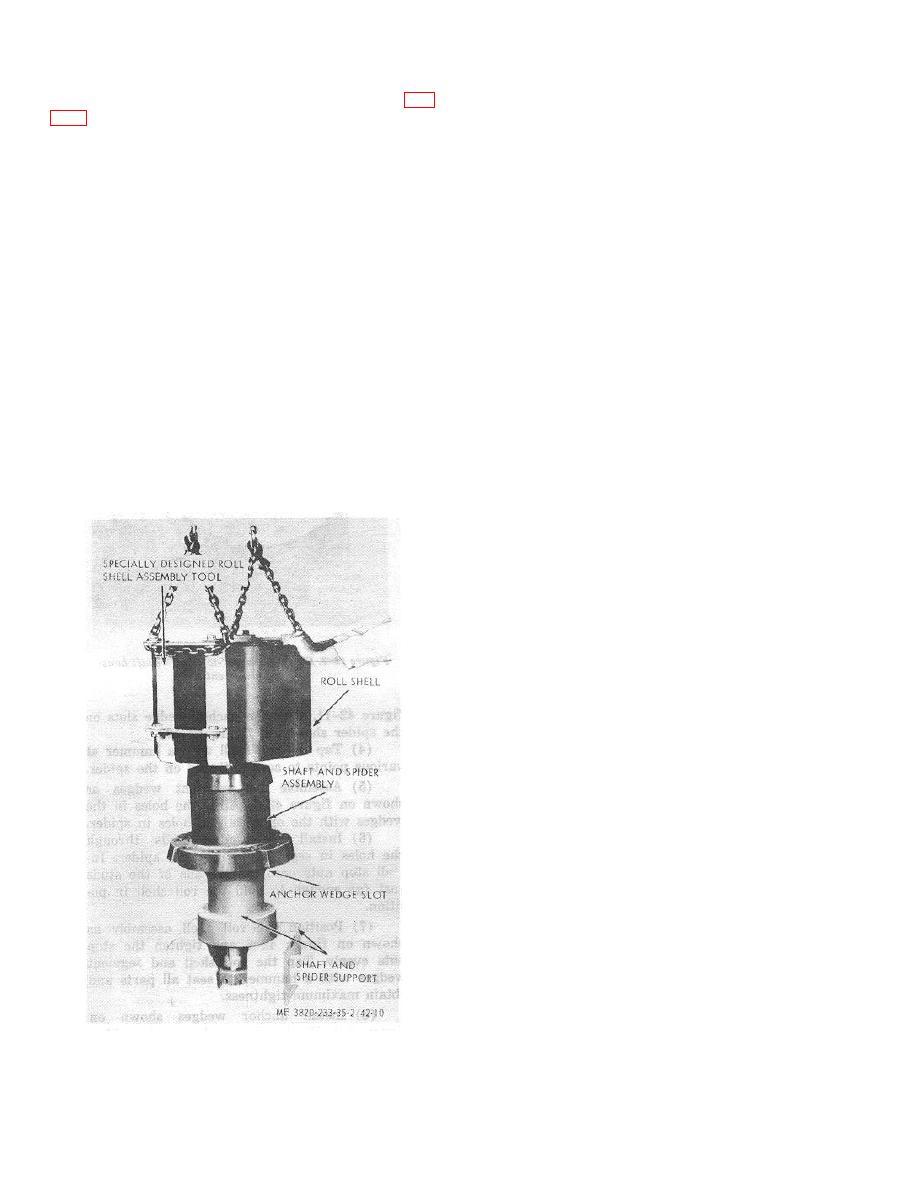

Figure 42-10. Roll shell assembly.

4-50