TM 5-3820-233-35/2

(7) Center

countershaft

in

housing.

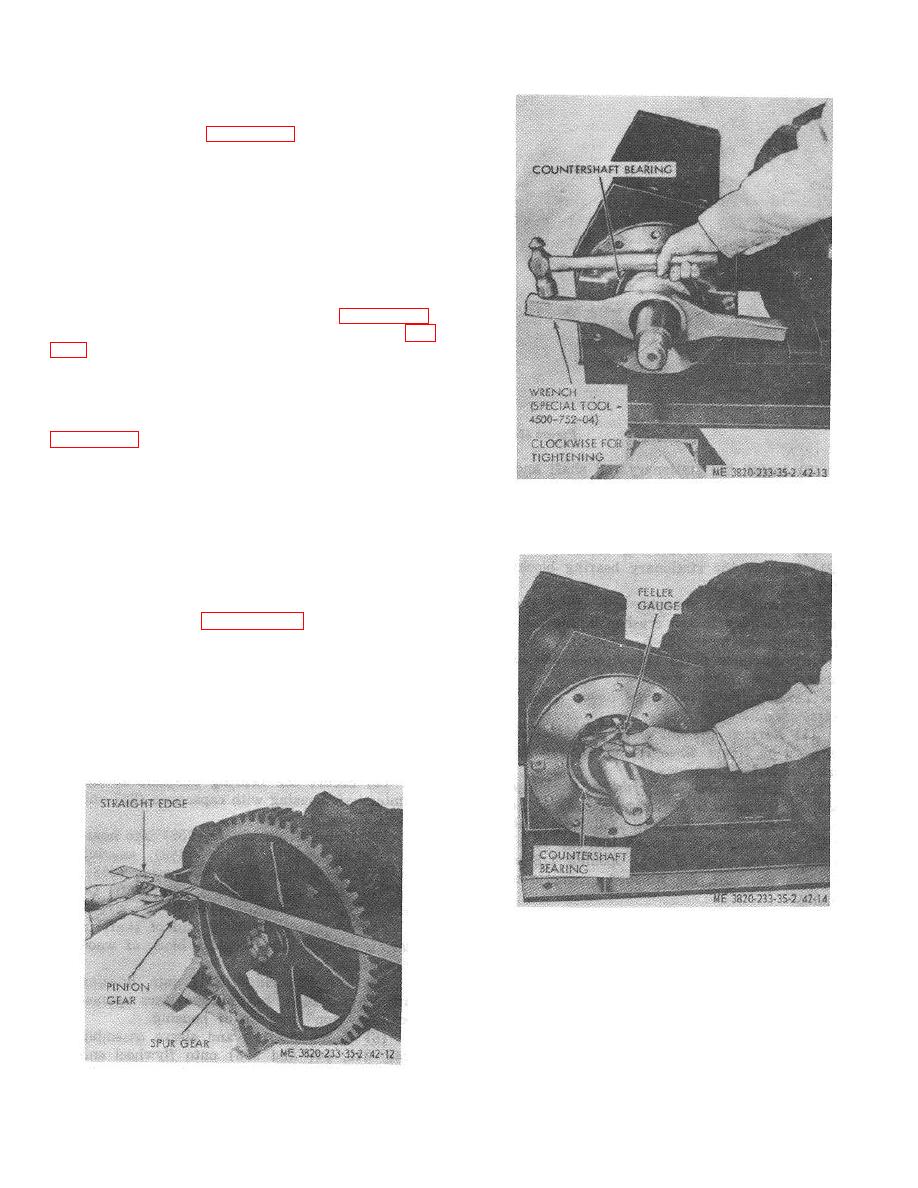

Temporarily install pinion and spur gears on shafts for

alinement as shown on figure 42-12.

Note

The pinion gear is approximately 1/4

inch larger across the face than the

spur gear, permitting a little flexibility

of countershaft location and still

maintaining

100

percent

gear

contact.

(8) Tighten lock nut (245) with wrench

(Special Tool-45500-752-404) as shown on figure 42-13.

There should be no contact between sleeve (248, fig.

housing approximately 1/8 inch.

Allow 1/4 inch

clearance from face of housing to sleeve.

(9) Measure the radial clearance between the

outer race of the bearing and the rollers as shown on

Note.

If the minimum 0.003 inch clearance

cannot be obtained tighten lock until

Figure 42-13. Loosening countershaft bearing.

no further takeup is noted. Over

tightening of the lock nut will stretch

the nut or sleeve threads.

The

bearing assembly must be tight to

keep sleeve from rotating on the

countershaft.

The

clearances

indicated on figure 42-14 are based

on one-half of the unmounted

hearing clearance.

(10) After the lock nut has been properly

tightened, turn the lock nut until one of the prongs on

lockwasher (246) lines up with a slot on the lock nut.

Bend prong in slot with drift pin or punch.

Figure 42-14. Measuring bearing clearance.

Figure 42-12. Spur and pinion gear alinement.

4-52