16.

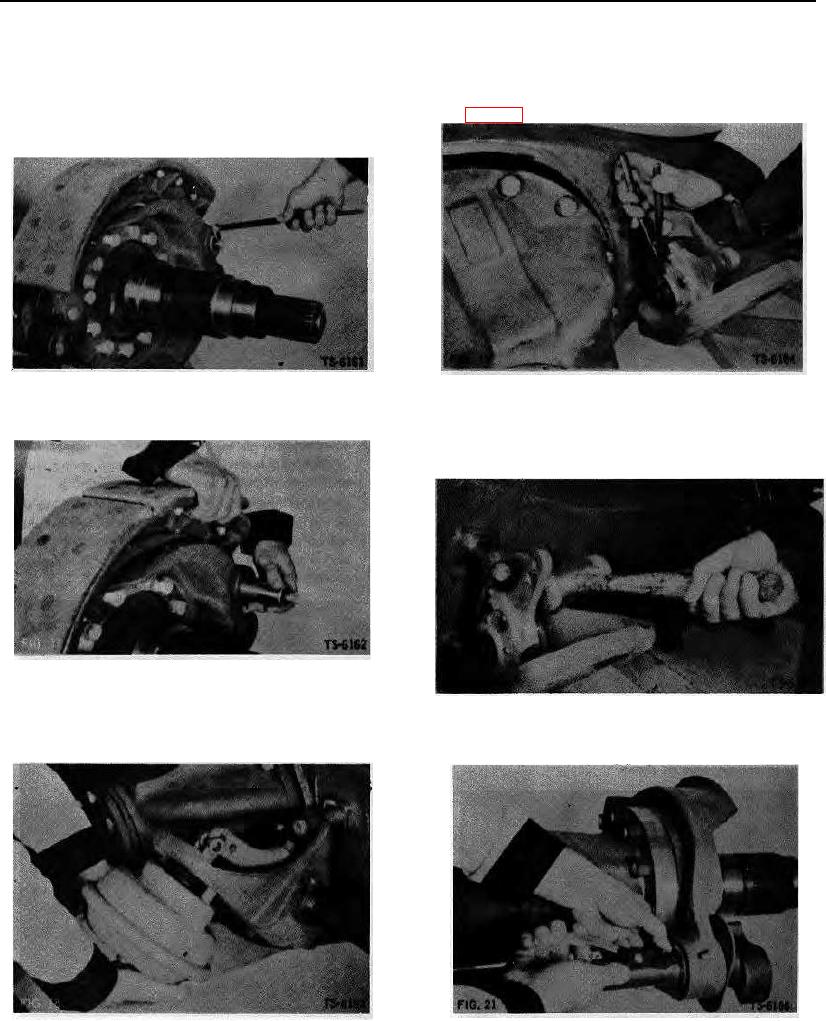

Cut lockwire and remove anchor pin set screws.

19. Remove slack adjuster retaining ring (Fig. 19).

Unscrew bolt in anchor pin several turns. Use pry

Remove slack adjuster retaining washer. Note

bar under screw head to start anchor pin from

position of slack adjuster adjusting screw. In some

spindle support assembly (Fig.

16). NOTE:

applications, screw is adjacent to air chamber

Anchor pins of some axle models are held in,

bracket. In other applications, it is as shown in

place by retaining plate and bolt. Remove bolt

and' anchor plate to remove pins.

17. Remove anchor pin and remove brake shoe (Fig.

17).

20.

Use soft mallet to drive slack adjuster from

brake

cam shaft (Fig. 20).

18. Remove cotter pin and pin securing clevis of air

chamber to slack adjuster. Remove nuts and lock-

washers securing air chamber to air chamber

bracket; remove air chamber (Fig. 18). ,

21. Unseat retaining ring that holds

cam

shaft

positioned in brake spider (Fig. 21).

18