28. Remove two bolts and lock washers that secure air

chamber bracket to axle housing; remove bracket

and spacers (Fig. 281.

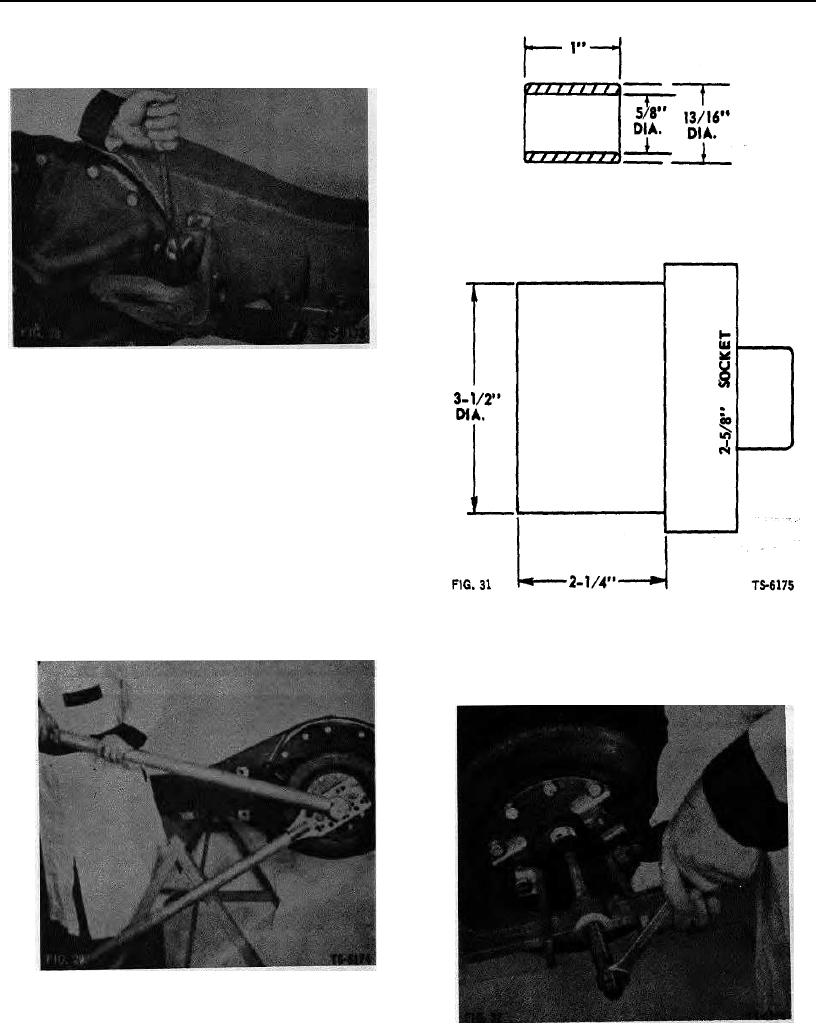

1/32" DIA RADIUS ALL CORNERS

FIG. 30

TS-5685

29 Disassemble opposite side of axle

following

instructions given in steps 2 through 28.

30. If axle is equipped with parking brake, proceed as

indicated below. If axle is not equipped with parking

brake, proceed to step 39. Position socket on

flange nut and then install flange retaining tool with

two spacers between tool and flange. Spacer

dimensions are given in Fig. 30. Loosen flange nut

(Fig. 29). Re- move flange retaining tool and

remove flange nut and washer.

NOTE: Standard 2 % -inch socket will not fit flange

nut because socket wall is too thick to enter recess

In flange. Machine socket as shown in Fig. 31 to

provide proper clearance.

31.

Use suitable puller to pull assembled companion

flange and parking brake drum from pinion shaft

(Fig. 32).

20