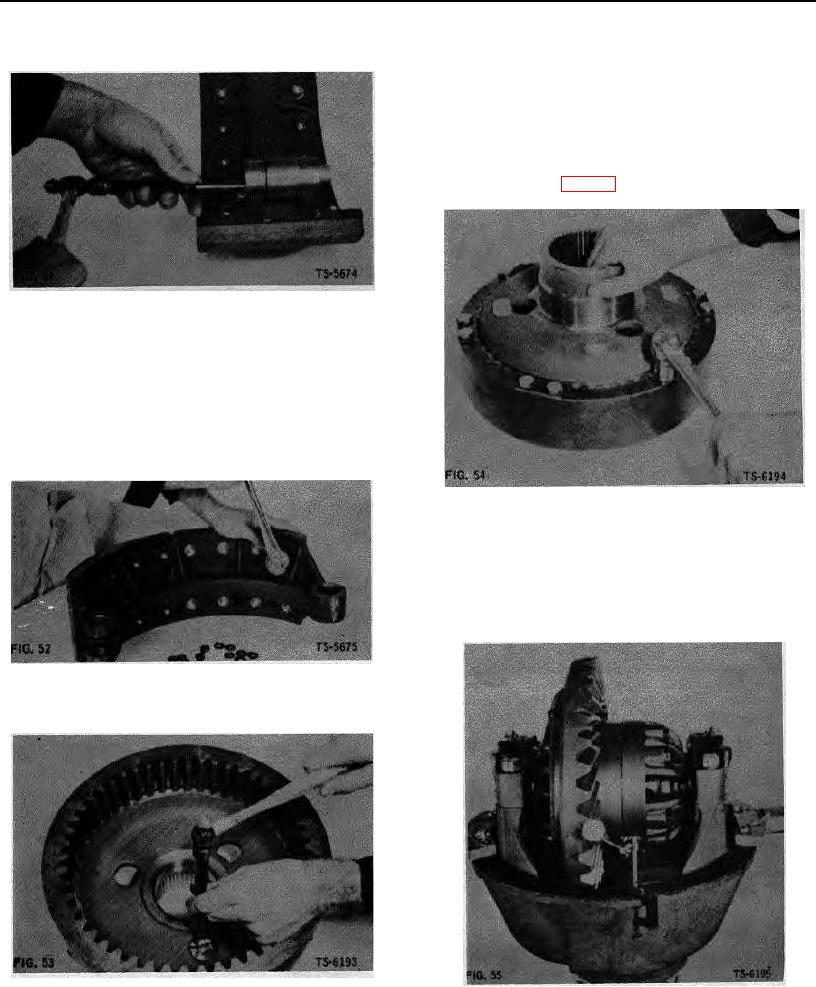

3. Drive out cam roller pin (Fig. 51). Remove roller.

2. If replacement of internal gear is necessary, cut

lock- wires and remove bolts securing internal gear

to hub (Fig. 54). Separate internal gear from hub.

NOTE: On some axle models, internal gears are

se- cured to hubs with bolts inserted through drilled

holes in internal gear and screwed into hub instead

of as shown in Fig. 54.

4. Check brake lining for oil or grease saturation,

wear, and looseness. If loose, tighten retaining

bolts to 200 to 220 inch-pounds torque. If saturated

with grease, replace all lining blocks. To remove

linings, remove nuts, lockwashers, and bolts

retaining lining to shoes (Fig. 52).

NOTE: When replacing brake linings, all linings on

both sides of axle assembly should be replaced at

the same time.

Disassembly of Differential and Carrier

1. Mount differential on differential overhaul stand.

Check and record ring gear backlash with dial

indicator.

This information is necessary for

reassembly unless a new gear set is installed (Fig.

55).

Disassembly of Internal Gear and Hub

1.

Drive bearing cone from hub (Fig. 53).

24