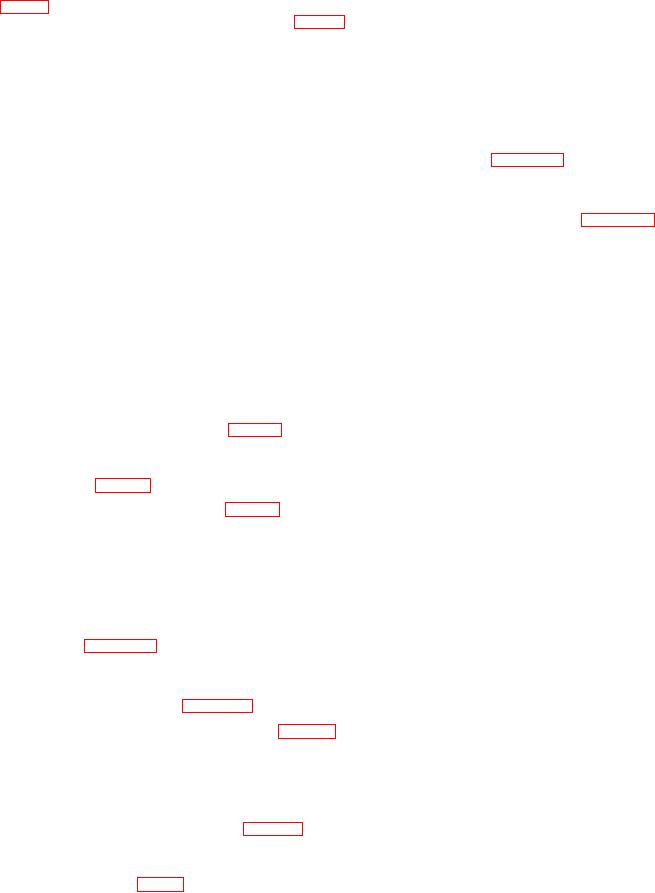

Note. Do not install the cover band assembly (1, B,

b. Installation. Install the generator (TM 5-

fig. 15) or insert the brushes (4) in the brush holders

3820-205--20/l).

until the armature and drive end frame (A, fig. 16)

have been reassembled and installed.

Section

V.

STARTING

MOTOR

53. General

the motor drive housing in the nu-

m e r i c a l sequence as illustrated on C

T h e engine starting motor is a 6-pole, 24-

and D, figure 16.

v o l t , dc-type. When energized by the starter

(8) Disassemble the field coils, frame, and

solenoid, the drive pinion of the starting motor

pole shoes in the numerical sequence

engages with the ring gear on the flywheel and

as illustrated on E, figure 16.

cranks the engine at the proper speed for

s t a r t i n g . When the engine starts, the drive of

the starting motor disengages the drive pinion

55. Starting Motor Cleaning, Inspection,

from the ring gear on the engine flywheel.

Testing, and Repair

a . Cleaning.

54. Starting Motor Removal

(1) Clean a dirty or discolored armature

and Disassembly.

commutator with No. 00 sandpaper

a. Removal. Remove the starting motor and

and blow out sand with clean, dry,

s o l e n o i d (TM 5-3820-205-20/1).

c o m p r e s s e d air. Remove all dirt and

c h i p s from the commutator bars.

b. Disassembly.

( 2 ) Clean the brushes with a clean, dry

( 1 ) Remove the bolts (1, A, fig. 16) wash-

c l o t h . Do not clean the brushes with

e r s (2) and remove the assembled end

solvent.

bell (3) and brush holder assembly

(B, fig. 16).

(3) Clean the frame and field coils with a

cloth dampened with an approved

( 2 ) Remove items (4-9, A, fig. 16) in nu-

c l e a n i n g solvent and dry with clean,

merical sequence and remove the

d r y compressed air. Do not soak the

b r u s h and holder assembly from the

insulation of the field coils in solvent.

end bell.

( 4 ) Clean the armature with compressed

(3) D i s a s s e m b l e t h e r e m a i n i n g i t e m s o f

a i r to remove any dust or dirt, Wipe

t h e commutator end frame in the nu-

t h e armature with a cloth dampened

merical sequence as illustrated on

with an approved cleaning solvent;

A, figure 16.

dry with clean, compressed air.

( 4 ) D i s a s s e m b l e the brush and holder as-

( 5 ) Clean the motor drive housing with a

s e m b l y in the numerical sequence as

cloth dampened with an approved

illustrated on B, figure 16.

c l e a n i n g solvent and dry with clean,

( 5 ) Remove the capscrews (1, C, fig. 16),

dry, compressed air.

washers (2) and remove the assem-

(6) C l e a n a l l o t h e r m e t a l p a r t s w i t h a n

b l e d motor drive housing, armature,

approved cleaning solvent and dry

and drive assembly from the starter

thoroughly.

frame.

(6) Remove items (l-5, D, fig. 16) and

b . Inspection, Testing, and Repair.

s e p a r a t e the assembled armature (6)

(1) Inspect the commutator for roughness

from the assembled motor drive hous-

o r out-of-round. Mount the armature

ing (3, C, fig.16).

with its bearing surfaces on V-blocks

(7) Disassemble the remaining items in

and measure the commutator runout

t h e armature and drive assembly and

with a dial indicator. Turn down a

45

AG0 8489A