Note. When installing the body assembly (31, fig. 17)

60. Overspeed Governor Assembly

compress the retaining ring (22) and seat it in the

Reassembly and Installation.

groove in the body assembly.

a. Reassembly. Refer to figure 17, and reas-

b. Installation. Install the overspeed gov-

s e m b l e the overspeed governor in the reverse

e r n o r assembly (TM 5-3820-205-20/l).

order.

Note. When reassembling the governor fill the cavity

Section

VII.

FUEL

INJECTOR

ASSEMBLIES

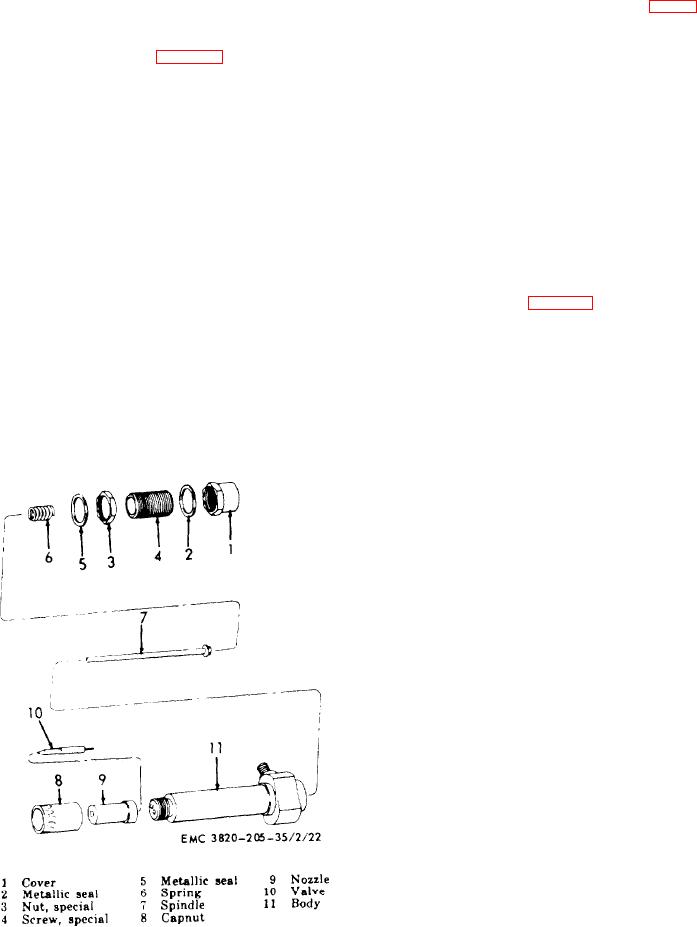

62. Fuel Injector Assemblies Removal

61. General

and Disassembly

The fuel injector assemblies on the roll

a. Removal. Remove the fuel injector assem-

c r u s h e r engine have pintle-type nozzles. They

blies (TM 5-3820-205-20/l).

inject the fuel oil into the cylinders of the

d i e s e l engine at a high-pressure (1,750-1,850

b . Disassembly. Refer to figure 18, and dis-

psi). The fuel injectors are held in the engine

assemble the fuel injector assembly.

b l o c k by a holddown yoke secured with studs

and nuts. There are two fuel lines attached to

t h e injector, one the high pressure line from

63. Fuel lniector Assemblies Cleaning,

t h e injection pump, and the other the excess

Inspection, and Repair

fuel return line to the pump.

a. Cleaning.

(1) Clean all carbon off the nozzle and

valve. Do not use sharp tools or abra-

sives.

(2) Clean the remaining parts of the fuel

injector in an approved cleaning sol-

vent.

C a u t i o n : Do not touch any polished

surface with the fingers after flushing.

Moisture from the fingers will cause

corrosion.

b. Inspection and Repair.

(1) I n s p e c t t h e s p i n d l e a n d s p r i n g f o r

damage or wear. A pitted or corroded

s p r i n g must be replaced. Replace all

defective parts.

( 2 ) Inspect the holder and be sure all pas-

sages are clean.

(3) Inspect all threaded parts of the fuel

injector for damage to threads. Re-

place all parts having defective

threads.

( 4 ) Inspect the metallic seals and gaskets

for wear and damage. Replace a worn

or damaged seal or gasket.

Figure 18. Fuel injector assembly, exploded view.

50

AGO 8498A