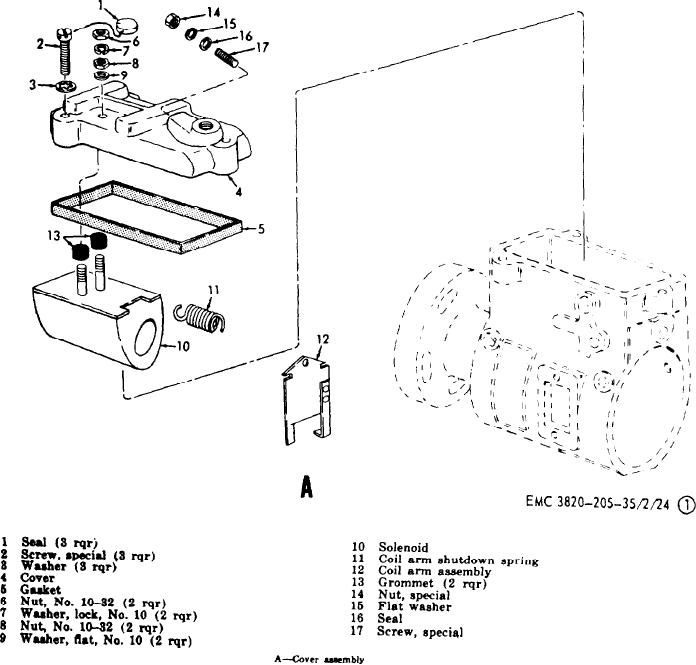

Figure 20. Fuel injection pump and governor assembly, exploded view.

b. Inspection and Repair.

thread damage, cracks, and distortion.

Replace all defective parts.

(1) Inspect all packing, seals, and gaskets

(3) Inspect the regulating plunger, rotor,

for distortion or damage, and all

plungers, distributor rotor, cam roll-

springs for wear, distortion, and

ers and shoes, governor weights, gov-

breakage. Carefully inspect all bores,

ernor linkage, and metering valve for

g r o o v e s , and seal seats for damage.

f r e e d o m of movement. If any parts

Replace any defective parts.

are sticking, but not visibly damaged,

( 2 ) Inspect each part of the injection

c l e a n the parts thoroughly with an

pump for wear, foreign material, rust,

a p p r o v e d cleaning solvent. Replace

nicks, chipping, s c r a t c h e s , scores,

any parts that do not move freely.

53

AGO 8498A