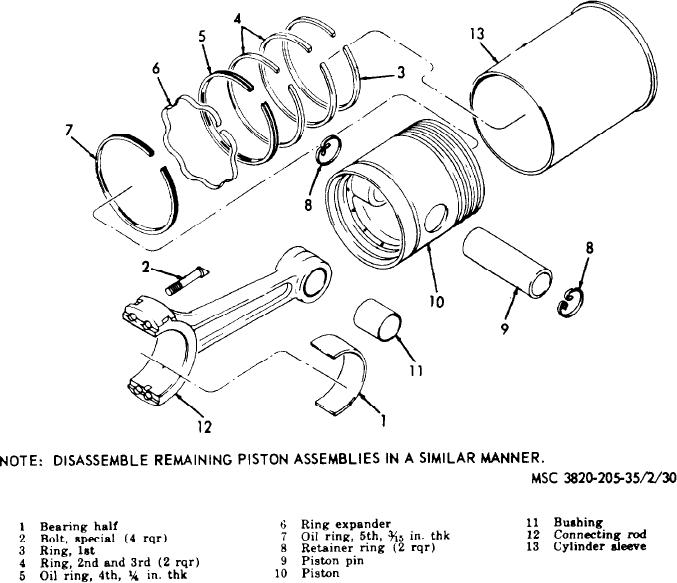

Figure 33. Piston, sleeve, and connecting rod assembly, exploded view.

f r o m 1.7503 to 1.7505 inch. Replace

(7) Install the piston rings in the respec-

connecting rod bushings that are worn

tive cylinder sleeve and check for

m o r e than 1.7515 inch in diameter.

p r o p e r ring gap with a feeIer gage.

T h e proper ring gap is from 0.018 to

( 1 0 ) Clamp the connecting rod and piston

0 . 0 3 2 inch. If the ring gap is smaller

a s s e m b l y without rings on the man-

than that specified, dress off the ends

drel with an alining fixture, and with

of the rings squarely with a file.

the connecting rod bearings in place.

Check the gap between the surface

( 8 ) Measure the piston pins with an out-

plate and the piston along the piston

s i d e micrometer for proper diameter

skirt, with the piston held at several

of 1.7500 to 1.7498 inch. Replace pis-

a n g l e s to the connecting rod. If the

ton pins with a diameter smaller than

gap is not the same at all angles, the

1.7495 inch.

connecting rod is twisted and must be

( 9 ) Inspect the connecting rod bushings

replaced.

for scoring, scratches, and other indi-

( 1 1 ) Hold the piston parallel to the con-

c a t i o n of wear and damage. Measure

necting rod and check the gap between

t h e i r diameter with a pair of inside

the piston skirt and the surface plate.

m i c r o m e t e r s . Proper measurement is

74

AGO 8498A