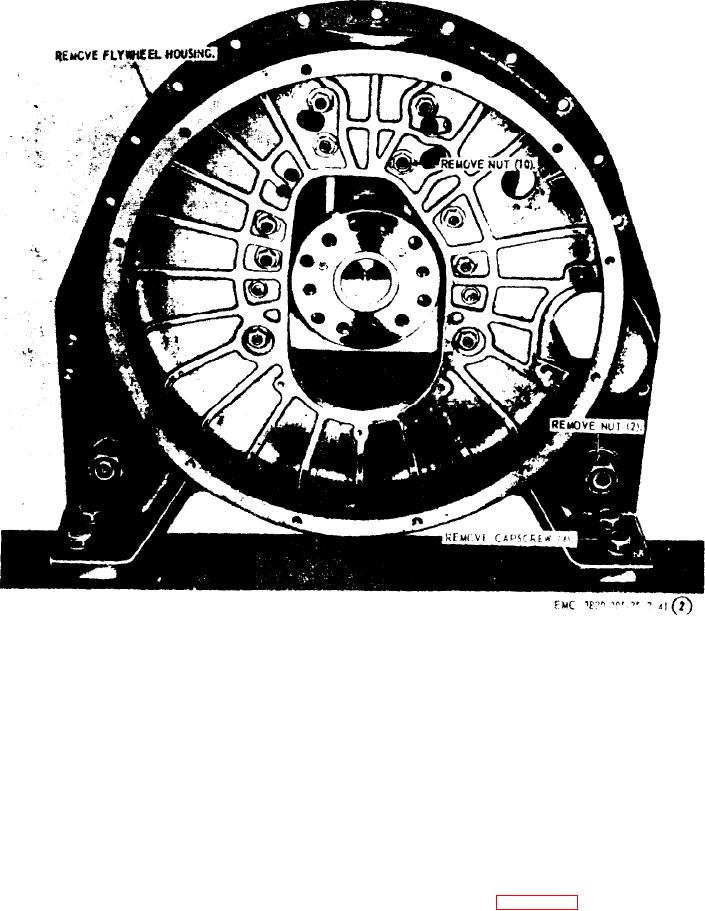

Figure 35 --Continued.

Section

XIX.

MAIN

BEARINGS

AND

CRANKSHAFT

109. General

110. Main Bearings and Crankshaft

Removal and Disassembly

The crankshaft is supported by seven main

bearings. The end and center main bearings

a. Removal.

are different, whereas the four intermediate

(1) R e m o v e t i m i n g g e a r s a n d f r o n t e n d

main bearings are alike. The front main bear-

p l a t e (par. 86).

i n g is polished on one side to back up a brass

( 2 ) R e m o v e flywheel housing (par. 106).

thrust ring, which is instahed between the

(3) R e m o v e connecting rod bearing caps

f r o n t main bearing and the first throw of the

( p a r . 98).

crankshaft. Dowel pins in the block locate the

bearing caps accurately to the block. The jour-

(4) Refer to figure 36, and remove the

n a l s of the crankshaft are hardened to resist

main bearings and crankshaft from

wear and scoring.

the engine.

AGO 8498A