d i a m e t e r for the camshaft journaI is

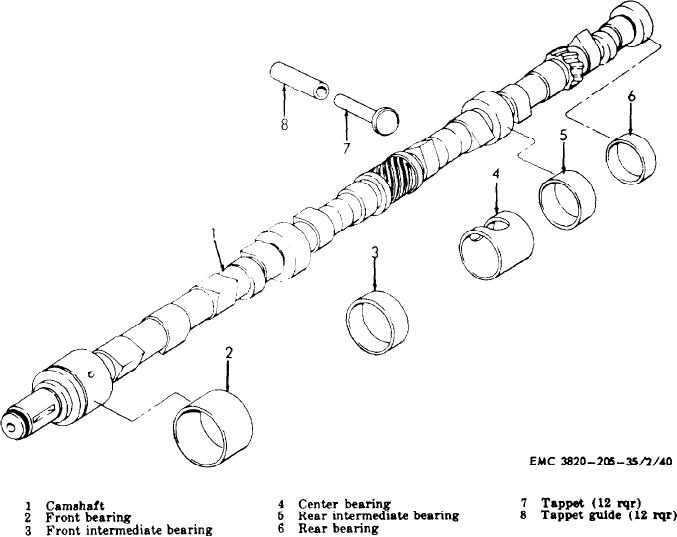

103. Camshaft, Bearings, Tappets, and

2 . 2 4 7 5 to 2.2480 inch If any journal

Tappet Guides, Cleaning,

is worn less than 2.2465 inch, replace

Inspection, and Repair

t h e camshaft.

a. Cleaning. Clean all parts with an ap

( 4 ) I n s p e c t the gear on the camshaft for

proved cleaning solvent and dry thoroughly.

w o r n , broken, or chipped teeth. Re-

b. Inspection and Repair.

place the camshaft if the gear is

(1) Measure the diameter of the tappets

damaged.

w i t h a pair of outside micrometers.

The proper diameter should be 0.6082

104. Camshaft, Bearings, Tappets, and

t o 0.6087 inch. If the tappet is worn

Tappet Guides Installation

less than 0.6072 inch, replace the

tappet.

a. Press the bearings (2, 3, 4, 5, and 6, fig.

(2) I n s p e c t t h e t a p p e t s f o r s c o r i n g o r

34) into the engine block.

damage to the contact surface. Re-

Note. Before pressing the bearings in the engine

p l a c e badly pitted or scored tappet.

block make certain that the oil passages are in correct

(3) M e a s u r e t h e c a m s h a f t j o u r n a l s w i t h

alinement, and press bushings carefully to prevent

an outside micrometer. The proper

damage.

76

AGO 8498A