SECTION IV. TAIL SECTION CONVEYOR HOPPER ASSEMBLY

184. General

b. Remove the tail section of the discharge

conveyor assembly (par. 84).

The conveyor hopper assembly ;a rigidly mounted

to the tail section of the conveyor and consists of a

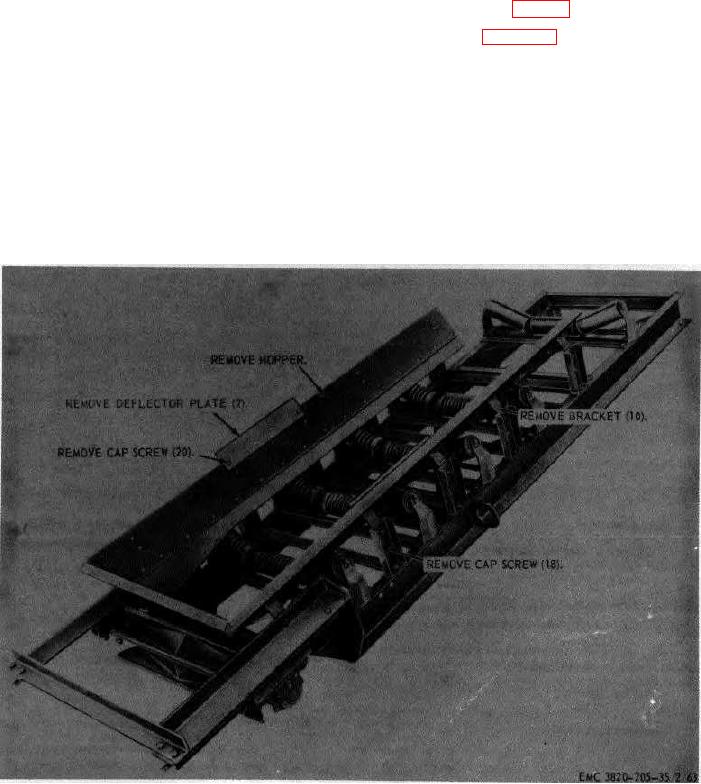

c. Refer to figure 54 and remove the tail section

hopper, liner, deflector plates, and liner strips. The

conveyor hopper assembly from the unit.

hopper acts as a means of receiving and positioning the

186. Tail Section Conveyor Hopper

Assembly

desired material on the discharge conveyor belt. The

Cleaning, Inspection, and Repair

liners prevent the material from falling off the belt due to

heaping or overloading.

a. Cleaning. Clean all parts with an approved

cleaning solvent. Dry thoroughly.

185. Tail Section

Conveyor

Hopper

Assembly

Removal

b. Inspection and Repair. Inspect all parts for

cracks, breaks, wear, distortion, and other damage.

a. Remove the liners and strips (TM 5-3820-205-

Replace or repair all unserviceable parts as necessary.

20/2).

Figure 54. Conveyor hopper assembly, removal and installation.

AGO 3456A

104