CHAPTER 10

JAW CRUSHER MAIN FRAME ASSEMBLY REPAIR

INSTRUCTIONS

228. General

(13) Remove the air tank, relay valve, air

filters, connectors, and airlines and fittings

The jaw crusher main frame assembly consists of

three parts, and engine frame assembly and an upright

support which are bolted to the welded horizontal main

(14) Remove the main control panel and

frame assembly.

operator's control box (pars. 218 and

221).

229. Main

Frame

Assembly

Removal

and

Disassembly

(15) Remove the engine assembly (par. 30).

a. Removal.

(16) Remove the pan feeder assembly (par.

(1) Remove the dolly assembly (TM 5-3820-

205-20/2).

(17) Remove the vibrating scalper screen

assembly (par. 32).

(2) Remove the platforms and ladders (TM 5-

3820-205-20/2).

(18) Remove the crusher unit assembly (par

33).

(3) Remove the fuel tank and brackets (TM 5-

3820-205-20/2).

(19) Remove

the

discharge

conveyor

assembly (par. 34).

(4) Remove the jacks (TM 5-3820-205-20/2).

(20) Remove the bogie

and

rear

axle

(5) Remove the pintle hook and mounting

assembly (par. 35).

bracket (TM 5-3820-205-20/2).

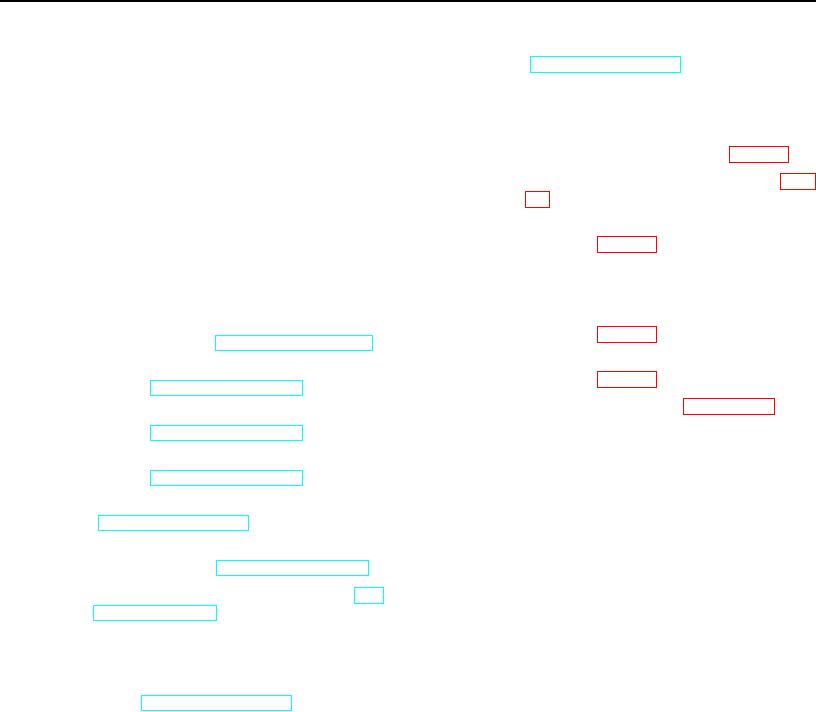

Refer to figure

and

b. Disassembly.

(6) Remove power cable reel, and mounting

disassemble the main frame assembly.

bracket (TM 5-3820-205-20/2).

230. Main Frame Assembly Cleaning, Inspection,

(7) Remove fire extinguisher and mounting

and Repair

bracket (TM 5-3820-205-20/2).

a. Cleaning. Clean all parts with an approved

(8) Remove toolbox and mounting brackets

cleaning solvent and dry thoroughly.

b. Inspection and Repair.

(9) Remove hydraulic cylinder, tank and

mounting bracket (TM 5-3820-205-20/2).

(1) Inspect the engine frame assembly for

cracks, bends, broken weldments, or other

(10) Remove the diverter box and chutes (TM

damage. Repair or replace as necessary.

(2) Inspect the vertical support beam for

(11) Remove the battery box (TM 5-3820-205-

cracks, bends, or elongated holes. Repair

20/2).

or replace as necessary.

(12) Remove the vibrating scalper screen

(3) Inspect the horizontal main frame

motor (TM 5-3820-205-20/2).

assembly for cracks, bends, broken

weldments, or other damage. Repair or

replace as necessary.

AGO 3456A

125