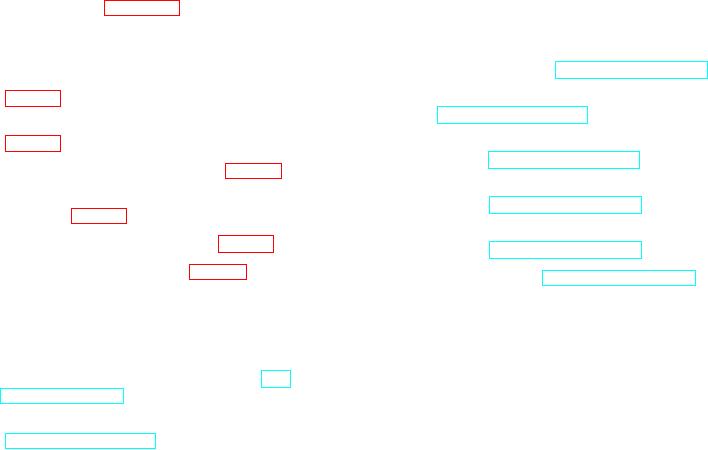

231. Main Frame

Assembly

Reassembly

and

(10) Install the battery box (TM 5-3820-205-

Installation

20/2).

(11) Install the diverter box and chutes (TM 5-

a. Reassembly. Refer to figure 66 and reassemble

3820-205-20/2).

the main frame assembly in the reverse order.

(12) Install the hydraulic cylinder, tank and

b. Installation.

mounting bracket (TM 5-3820-205-20/2).

(1) Install the bogie and rear axle assembly

(13) Install the toolbox and mounting brackets

(2) Install the discharge conveyor assembly

(14) Install the fire extinguisher and mounting

bracket (TM 5-3820-205 20/2).

(3) Install the crusher unit assembly (par. 33).

(15) Install the power cable reel and mounting

(4) Install the vibrating

scalper

screen

bracket (TM 5-3820-205-20/2).

assembly (par. 32).

(16) Install the pintle hook and mounting

(5) Install the pan feeder assembly (par. 31).

bracket (TM 5-3820-205-20/2).

(6) Install the engine assembly (par. 30).

(17) Install the jacks (TM 5-3820-205-20/2).

(7) Install the main control panel and

(18) Install the fuel tank and brackets (TM 5-

operator's control box (pars. 220 and

3820-205-20/2).

223).

(19) Install the platforms and ladders (TM 5-

(8) Install the air tank, relay valve, air filters,

3820-20520/2).

connectors, and airlines and fittings (TM

(20) Install the dolly assembly (TM 5-3820-

205-20/2).

(9) Install the vibrating scalper screen motor

AGO 3456A

127