TM 5-3820-233-12/1

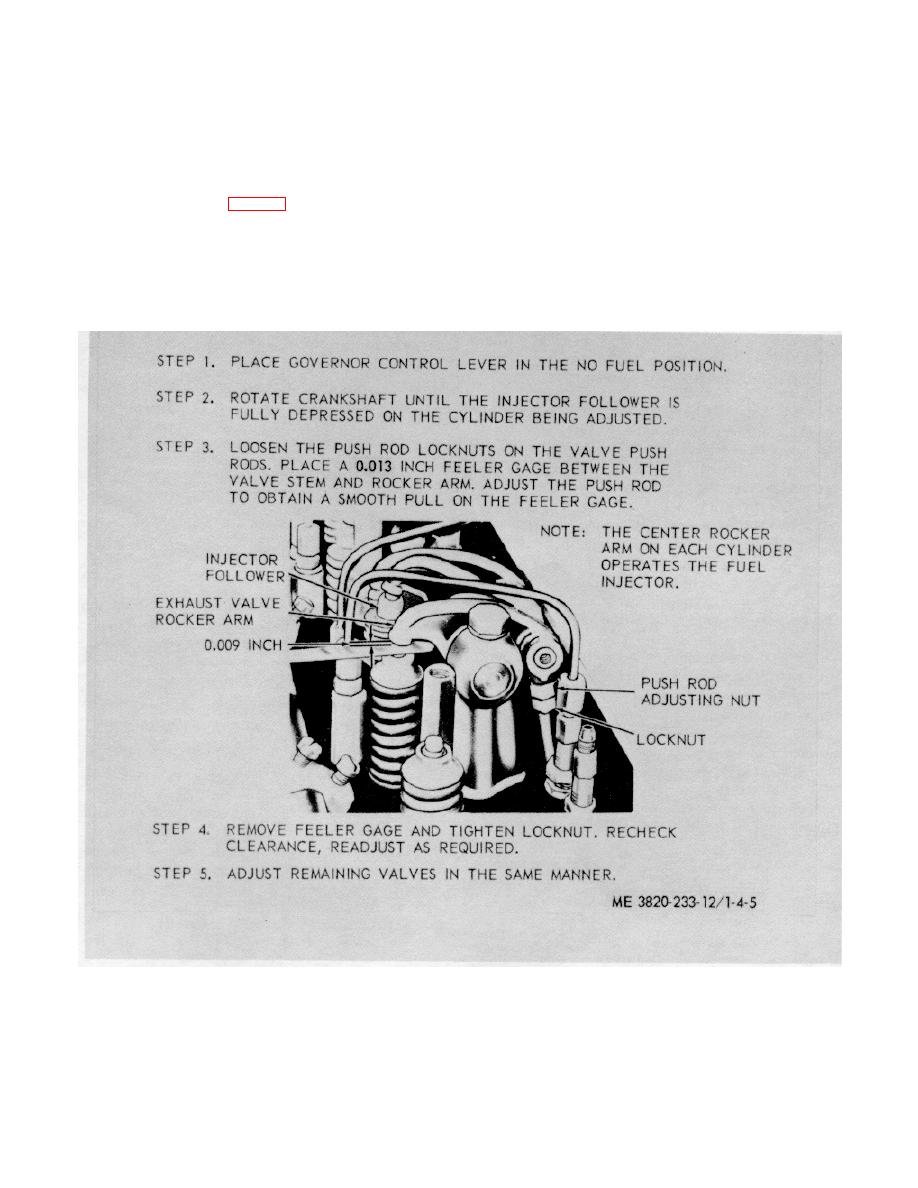

freely between the valve stem and the rocker arm, but

bolt at the front of the engine, do not

the 0.013 inch feeler gage will not pass through.

turn the crankshaft in a left hand

(7) Check and adjust the remaining valves in the

direction of rotation as the bolts will

same manner as outlined above.

be loosened.

c. Adjustment (Hot Engine).

(3) Loosen the push rod lock nut.

(1) Start engine and run until engine reaches normal

(4) Place a 0.013 inch feeler gage between the valve

operating temperature (160 to 185 F.).

stem and the rocker arm (fig. 4-5). Adjust the push rod

(2) Recheck the exhaust valve with a 0.008 inch

to obtain a smooth "pull" on the feeler gage.

feeler gage. If the valve clearance is correct the feeler

(5) Remove the feeler gage. Hold the push rod with

gage will pass freely between the valve stem and the

a 5/16 inch wrench and tighten the lock nut with a 1/2

rocker arm, but the 0.010 inch feeler gage will not pass

inch wrench.

through.

(6) Recheck the clearance. At this time, if the

adjustment is correct, the 0.011 feeler gage, will pass

Figure 4-5. Adjusting valve clearance.

4-8