TM 5-3820-233-12/1

Section VI. TROUBLESHOOTING

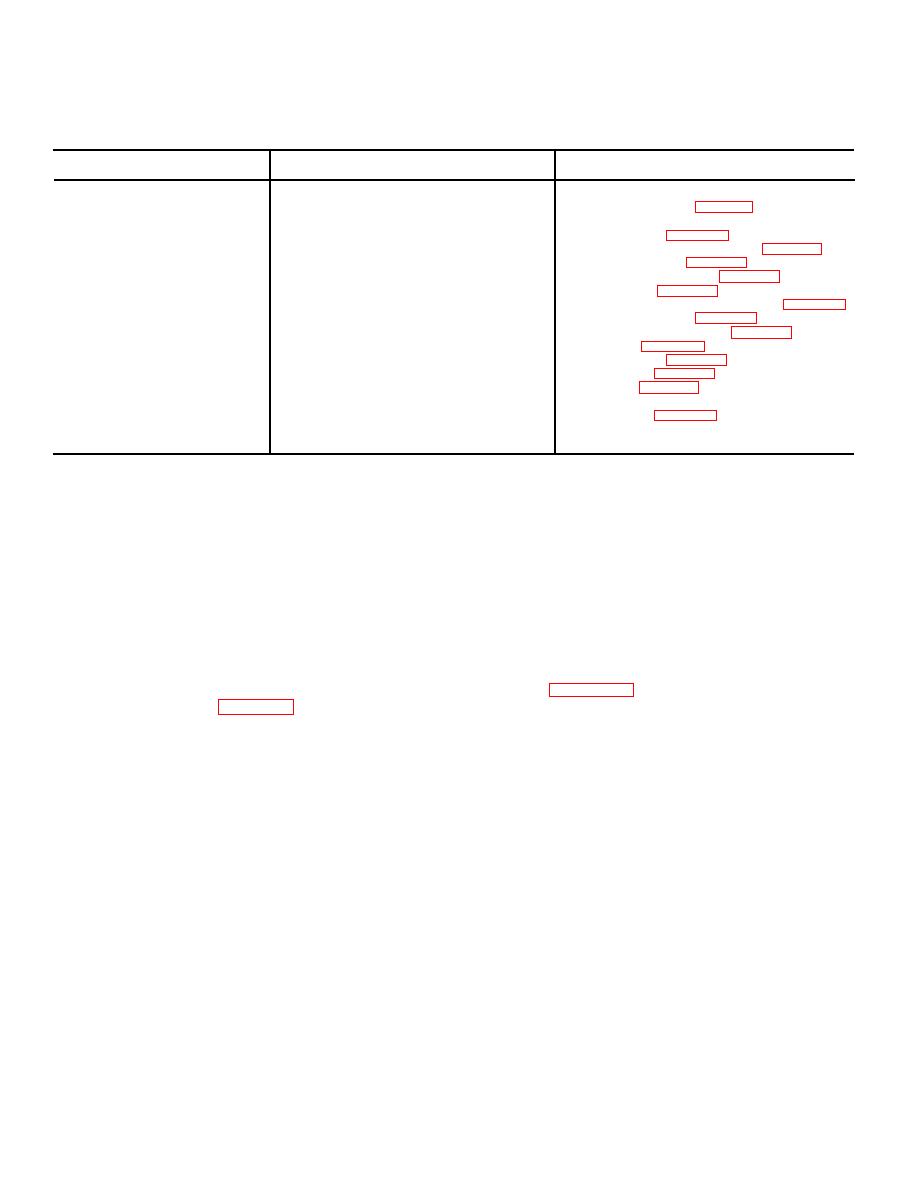

Table 4-2. Troubleshooting

Malfunction

Probable cause

Corrective action

1.

Starter Fails to Crank Engine.

a. Loose connection or defective wiring.

a. Tighten connection. Check continuity and

replace or repair wiring (para 4-41).

b. Defective starter switch.

b. Replace starter switch.

c. Defective starter.

c. Replace starter (para 4-41).

2. Engine Fails to Start.

a. Clogged fuel line or leaking line.

a. Clean line or replace leaking line (para 4-16).

b. Air cleaner dirty.

b. Service air cleaner (para 3-12).

3. Loss of Power.

a. Defective or clogged injection nozzles.

a. Clean or replace nozzles (para 4-13).

b. Inproper valve adjustment.

b. Adjust valves (para 4-14).

4. Engine Overheats.

a. Thermostat not functioning properly.

a. Test thermostat. Replace if defective (para 4-26).

b. Faulty water pump.

b. Replace water pump (para 4-28).

5. Engine Knocks.

Valve clearance incorrect.

Check and adjust if necessary (para 4-14).

6. Low or No Lubricating Oil Pressure. Defective gage.

Replace gage (para 4-46).

7. Jaw Crusher Capacity Low.

a. Discharge opening not adjusted.

a. Adjust opening (para 4-71).

b. V-belt slippage.

b. Adjust V-belt (para 4-56).

8. Feeder Clutch Slips.

Worn driving plates friction surface.

Adjust clutch (para 4-47).

9. Side and Pitman Bearing Overheats. Plant not level.

Level plant.

10. Conveyor Belt Slipping.

Drive pulley lagging worn.

Replace lagging (para 4-54).

Section VII. RADIO INTERFERENCE SUPPRESSION

functions which are incidental and/or secondary to their

4-7. General Methods Used to Attain Proper

primary function. They consist of external and internal

Suppression

tooth lockwashers used to attach electrical components

Essentially, suppression is attained by providing a low

for better grounding to the frame.

resistance path to ground for the stray currents. The

methods used include shielding the ignition and high

4-9. Inspection of Radio Interference Suppression

Components

straps, with using capacitors and resistors.

Inspect the shielded cable and ground straps for breaks,

cuts, and damage.

4-8. Interference Suppression Components

a. Primary Suppression Components. The primary

4-10. Replacement of Suppression Components

suppression components are those who primary function

Refer to figure 4-1 and remove and replace radio

is to suppress radio interference. These components are

interference suppression components.

described and located in figure 4-1.

b. Secondary Suppression Components. These

components have radio interference suppression

4-3