TM 5-3820-233-12/1

b. The item numbers are listed consecutively and

indicate the sequence of minimum requirements Refer to

checks and services.

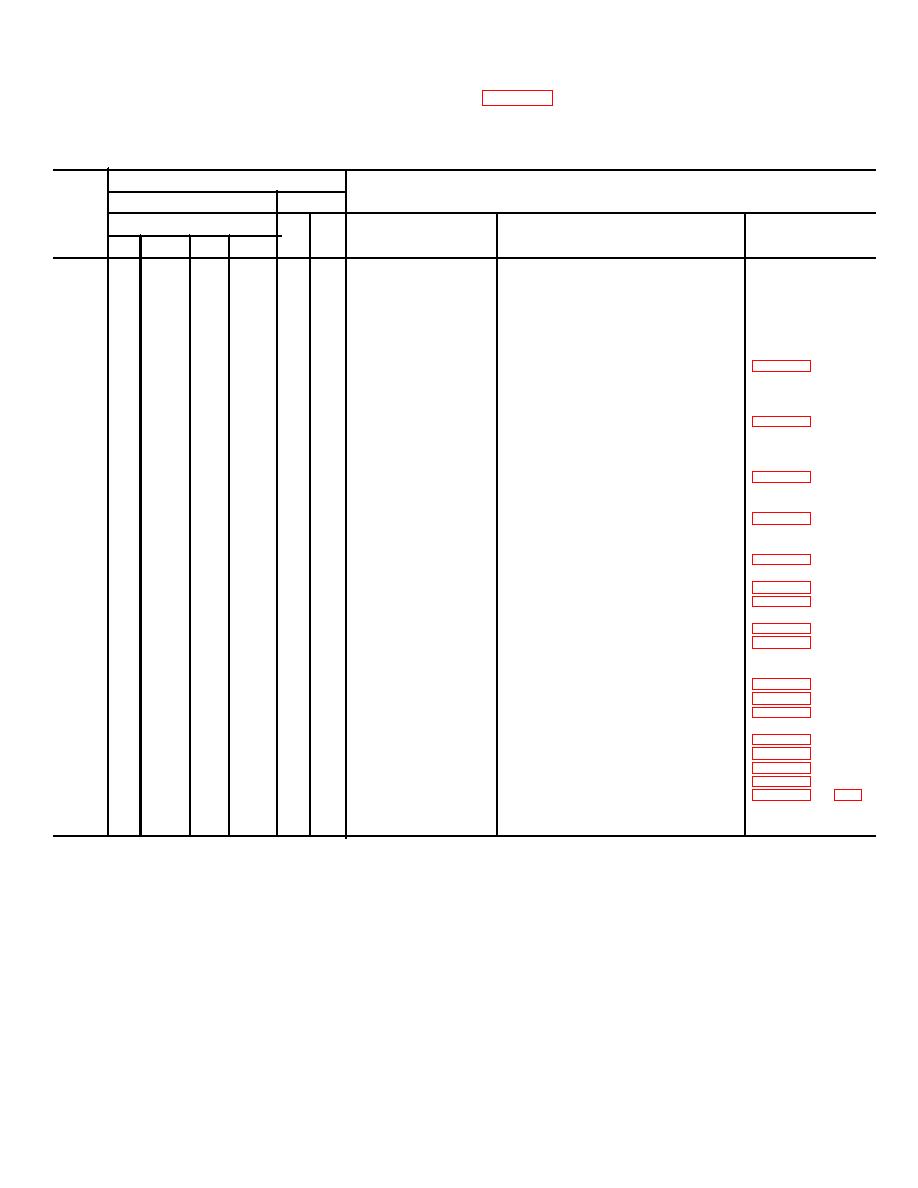

Table 4-1. Preventive Maintenance Checks and Services

Interval

B - Before operation

A - After Operation

M - Monthly

Operator

Org.

D - During Operation

W - Weekly

Q - Quarterly

Item

Daily

M

Q

Item to be inspected

Procedure

Reference

number

B

D

A

W

Lubricate in accordance

with current lubrication order

1

X

Oil Change

New engine oil change period is 100

LO 5-3820-233-12/1

hours

2

X

Cooling System

Check coolant level. Fill to overflow.

TB ORD 651

Check coolant anti-freeze solution.

Clean radiator air passages. Correct

coolant leaks.

3

X

Fuel System

Drain sediment from fuel filter. Check

fuel pump leaks (500 hours). Correct

all fuel leaks. Check fuel tank level.

Install new filter element (300 hours).

4

X

Air Cleaner

Change filter element when red flag locks

at top of indicator.

5

X

Air Box Drain Tubes

Check flow of air (1,000 hours). If tubes

are clogged remove, clean and reinstall.

6

X

Inspect commutator and brushes (500

hours). Clean commutator (2,000

hours).

7

X

Drive Belts

Check tension of belt (500 hours). Adjust

if necessary. Always replace drive belts

in sets.

8

X

Clutch

Check clutch facing for wear (500

hours). Adjust if necessary.

9

X

Pulley Lagging

Inspect lagging and replace if necessary.

10

X

Belting

Run conveyor and check for damage.

Repair if necessary.

11

X

Clutch

Check and adjust clutches.

12

X

Batteries

Tighten loose cables and mounting.

Remove corrosion. Replace cracked

or leaky battery.

13

X

Hopper Liners

Replace worn liners.

14

X

Feeder Wear Strips

Adjust or replace if worn excessively.

15

X

V-Belts

Check for worn or damaged belts.

Always replace in sets. Adjust if loose.

16

X

Jaw Crusher

Adjust discharge opening between jaws.

17

X

Jaws

Inspect for wear.

18

X

Key Plate

Inspect for wear, replace if necessary.

19

X

Movable Jaw 'Wedge

Check and tighten if necessary.

20

X

Lights

Test for proper operation.

4-2