TESTING AND ADJUSTMENT

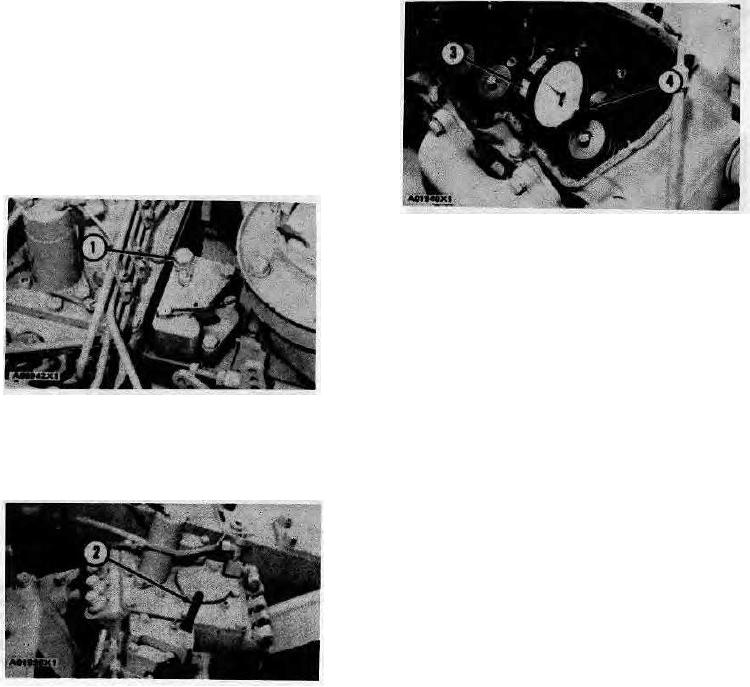

5. Put 8S2298 Adapter Group (4) and 9M9268 Dial

h. Remove bolt (3) from the timing gear and install in

Indicator (3) in the No.1 cylinder. Adjust dial indicator

hole (5). Install the plug in timing hole (4).

(3) so both pointers are on "0" (zero).

Remove timing pin (2) and install bolt (1). Install

cover for the tachometer drive assembly (6).

6. Turn the crankshaft COUNTERCLOCKWISE (as seen

from front of engine) a minimum of 45 decrees.

Checking Timing By Fuel Flow Method

Tools Needed: 3P1544 Timing Pin.

1P540 Flow Checking Tool Group.

9M9268 Dial Indicator.

Pan for holding the fuel.

5P2371 Puller.

8S2298 Adapter Group.

See Special Instruction (FM035709) for complete

instructions for the fuel flow method of engine timing

(injection sequence).

1. Remove bolt (1) from the timing pin hole.

DIAL INDICATOR INSTALLED

3. 9M9268 Dial Indicator. 4. 8S2298 Adapter

Group.

7. Turn the crankshaft CLOCKWISE (as seen from front

of engine) until dial indicator (3) gives an indication of

TIMING HOLE BOLT

maximum travel of the piston. Make an adjustment to

1. Bolt.

dial indicator (3), if necessary, to put both pointers of

the dial indicator on "0" (zero).

2. Turn the crankshaft CLOCKWISE (as seen from front of

engine) until timing pin (2) goes into the notch in the

8. Disconnect the fuel line for No.1 fuel injection pump at

camshaft for the fuel injection pumps.

the housing for the fuel injection pumps. Put 7M1999

Tube Assembly (8) on No.1 fuel injection pump and

tighten the nut. The position of the end of tube

assembly (8) must be a little above horizontal as

shown.

9. Disconnect the line for the supply of fuel at the fuel

filter.

Use an adapter to connect 5J4634 Hose

Assembly (9) to the fuel filter.

10. Disconnect the fuel return line from constant bleed

valve (5). Put cap (6) on the constant bleed valve.

TIMING PIN INSTALLED

2. 3P1544 Timing Pin.

11. Turn the crankshaft COUNTERCLOCKWISE (as seen

from front of engine) approximately 45 degrees.

3. Remove timing pin (2).

12. With 1 gal. (3.8 lit) of clean fuel in 1P539 Pressure

4. Remove the valve cover from the right side of the

tank (10), move the governor lever to full FUEL-ON

engine. Remove the fuel return line, rocker arm

position. Put 15 psi (1.1 kg/cm2) of air pressure in the

assembly, and the fuel injection nozzle for No.1

tank by using the hand pump or shop air.

cylinder.

56