TESTING AND ADJUSTMENT

TIMING

INDICATOR READING

ANGLE

15

.112 in.

2.84 mm

*16

.127 in.

3.23 mm

3.63 mm

17

.143 in.

*Correct timing angle

NOTE: If the timing of the fuel system is different than

the correct timing dimension given in the chart, see the

subject CHECKING TIMING BY TIMING PIN METHOD.

Checking Automatic Timing Advance Unit By

Timing Light Method

CONSTANT BLEED VALVE

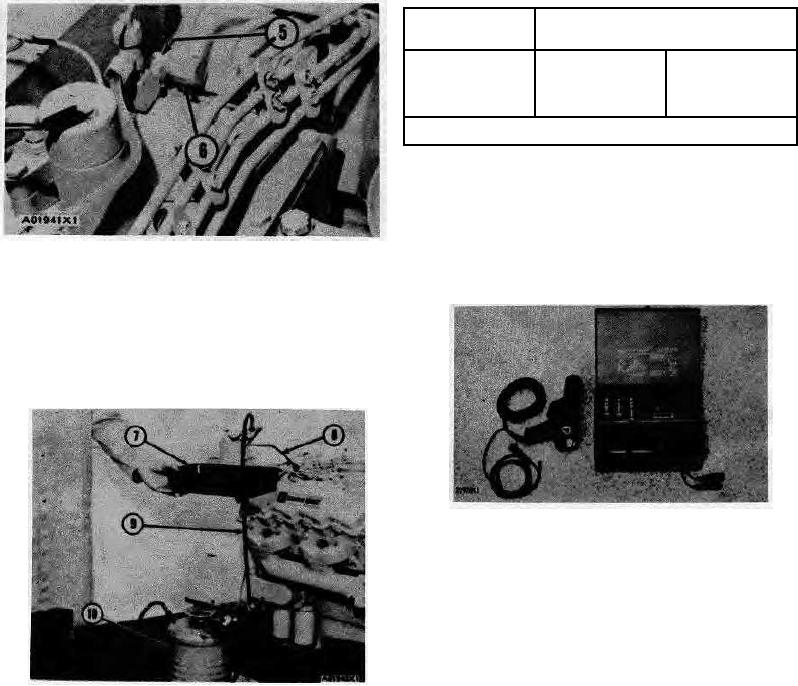

5. Constant bleed valve. 6. Cap.

Tools Needed: 1P3500 Injection Timing Group

CAUTION: If shop air is used, be sure to adjust the

2

regulator so there is no more than 15 psi (1.1 kg/cm ) of air

pressure in the tank.

13. Put pan (7) under the end of tube assembly (8) for the

fuel that comes out of the tube.

1P3500 INJECTION TIMING GROUP

This group can be used to check the automatic timing

advance. Special Instruction (GMG00501) is part of the

group and has detailed instructions for its use.

FUEL SETTING

Tools Needed: 3P1550 Field Service Tool Group

The following procedure for fuel setting can be done

with the housing for-the fuel injection pumps either on or

FUEL FLOW CHECK OF TIMING

off the engine.

7. Pan. 8. 7M1999 Tube Assembly. 9. 5J4634 How

Assembly. 10. 1P539 Pressure Tank.

CAUTION: Before doing any service work on this fuel

system, the outside of the housing for the fuel injection

14. Turn the crankshaft, slow, in the direction of normal

pumps and all parts connected to it must be especially

rotation CLOCKWISE (as seen from front of engine).

clean.

Do this until the flow of fuel from the end of tube

assembly (8) is 6 to 12 drops per minute.

1. Remove shut-off solenoid (1) and cover (2).

15. Stop rotation of the crankshaft when the flow of fuel is

2. Put the 5P298 Zero Set Pin (5), with 17.8507 on it, in

6 to 12 drops per minute. Take a reading of the

the pump housing.

measurement on dial indicator (3).

3. Put cover (3) and spring (4) over zero set pin (5). Do

16. To check for correct timing of the fuel system, make a

not put a gasket under cover (3). Use two 1D4533 Bolts

comparison of the reading on dial indicator (3) with the

with 4B4276 Washers and a 1D4538 Bolt to fasten

correct measurement in the chart.

cover (3) to the housing for the fuel injection pumps.

57