d. Install hopper assembly (par. 123).

139. Pan Feeder Apron Assembly Installation

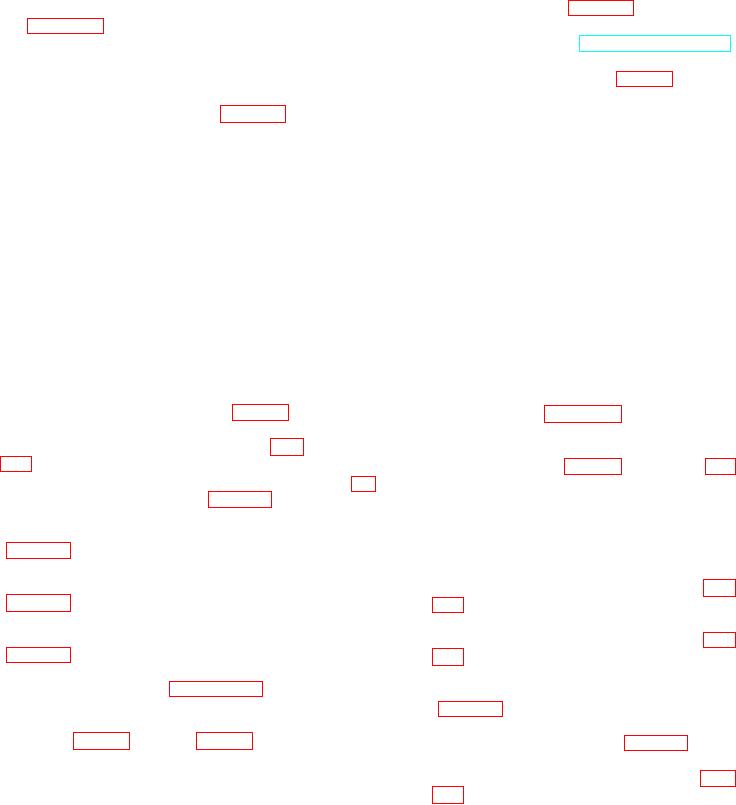

a Refer to figure 41 and install the pan feeder

e. Install electric drive motor (TM 5-3820-205-20/2).

assembly in the reverse order.

f. Install the pan feeder assembly (par. 31).

b. Install pans (TM 5-6820-205-20/2).

c. Install feeder gear reducer assembly (par. 127).

Section VII. FEEDER FRAME ASSEMBLY

142.

Feeder

Frame

Assembly

Cleaning

and

140. General

Inspection

The feeder frame assembly is a welded construction

which supports the drive shafts and sprockets, tail shaft

a. Cleaning. Clean all parts in an approved

and sprockets, adjustment assembly, roller bars, and all

cleaning solvent and dry thoroughly.

attaching parts for securing the pan feeder assembly on

the crusher.

b. Inspection. Inspect the frame for cracks, breaks,

distortion, warpage, elongated holes, or any other

141.

Feeder

Frame

Assembly

Removal

and

damage and replace or repair as necessary.

Disassembly

143.

Feeder Frame Assembly Reassembly and

a. Removal.

Installation

(1) Remove the pan feeder assembly (par. 31).

a. Reassembly. Refer to figure 42 and reassemble

the feeder frame assembly in the reverse order.

(2) Remove the electric motor assembly (par.

42(2)) through one side of the frame and install the keys

(3) Remove the hopper assembly (par. 121).

and sprockets before positioning the shaft in the

opposite side of the frame.

(4) Remove the feeder gear reducer assembly

b. Installation.

(5) Remove the feeder drive gear assembly

(1) Install the pan feeder apron assembly (par.

(6) Remove the pan feeder apron assembly

(2) Install the feeder drive gear assembly (par.

Refer to figure 42 and

b.

Disassembly.

(3) Install the feeder gear reducer assembly

disassemble the feeder frame assembly.

(4) Install the hopper assembly (par. 123).

be partially removed from the frame to allow sufficient

clearance for removal of the sprockets.

(5) Install the electric motor assembly (par.

(6) Install the pan feeder assembly (par. .31).

AGO 8456A

83