TM 5-3820-233-12/2

4-65. Vibrating Screen

on opposite side of box to maintain equal

The horizontal vibrating screen consists of three major

spring compression.

subassemblies: a welded steel base, a full floating screen

(5) Unscrew spring jack from jack nut.

box, and a screen vibrator unit. The base serves to support

b. Inspection.

the screen box and vibrator unit.

(1) Clean all parts, and coat threads of spring

4-66. Coil Springs

jack with motor oil.

Adjustable coil springs, placed between the base and

(2) Inspect spring for damage.

Replace a

screen box, prevent the weight of the screen box from

defective part.

c. Installation.

sagging the support springs.

a. Removal.

(1) Reassemble the coil spring, spring jack, jam

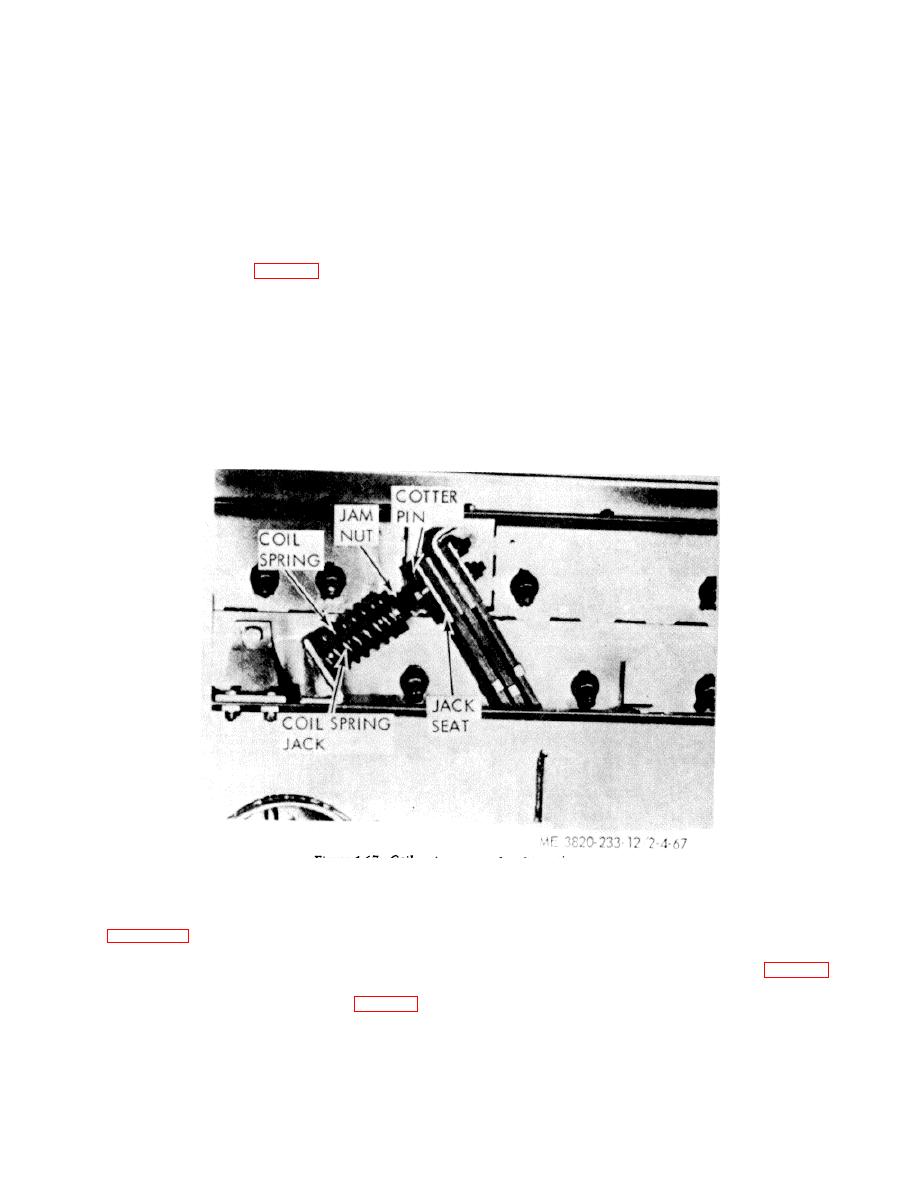

(1) Remove cotter pin (fig. 4-67).

nut and screw the spring jack far enough into the jack nut to

(2) Place a jack between screen box and base at

permit coil spring to slip between coil spring seat and coil

intake and before releasing compression on spring.

spring jack seat. Adjust jack to make contact with jack seat.

(3) Break jam nut loose from coil spring nut and

(2) Remove the jack supporting the screen box

thread the nut up the coil spring jack for disassembly.

and adjust the coil spring compression so the distance

(4) To release spring compression turn coil spring

between coils are 1/4" or less.

jack clockwise in jack nut. When compression is released

(3) Replace cotter pin locking the spring jack in the

remove coil spring and coil spring jack from screen.

coil spring bracket.

(4) Check compression of coil springs opposite

NOTE

each other.

When replacing broken spring, replace spring

(5) Tighten lock nut.

Figure 4-67. Coil spring, removal and installation.

compression until springs are equal length and leaf springs

4-67. Coil Spring Adjustment

are straight.

Refer to figure 4-68 and adjust the coil springs as follows:

d. Measure coil springs to insure that springs opposite

a. Break the jam nut loose from the coil spring nut.

each other are the same compression height (fig. 4-68B).

Thread the nut up the coil spring jack.

b. Remove cotter pin.

NOTE

c. Place a wrench on the coil spring jack (fig. 4-68A),

Where extremely hard material is being

turning the jack to increase or decrease

crushed, it may be necessary to compress the

springs to less than 1/4" between coils.

4-52