TM 5-3820-233-12/2

mover. The Model 2A-2B screening unit is equipped with

4-71. Size of Feed

13.00-221/2 DC

a. The size of material fed to the roll crusher is

discs wheels and 16:5 x 22: 5--16-ply tires, 65 lbs.

determined by the size of the discharge opening and

inflation.

diameter of the shells. Recommended sizes are shown in

NOTE

vary slightly.

Both the secondary screening unit and the

b. Material fed into the roll crusher must be of a size

dolly have the same wheel, tire and service

or reduced to a size which the roll crusher is capable of

brake arrangement and can be removed in the

crushing, to a further reduced finished specified

same manner.

aggregate.

b. Removal and Disassembly. Refer to figure 4-72

c. Generally, an additional crusher must be used to

and remove and disassemble the wheel, tire, and brake

handle the primary crushing to reduce oversized material

assembly as follows:

to a size readily handled by the secondary roll crusher.

(1) Remove the ten cap nuts (1, fig. 4-72) and

NOTE

remove wheel assembly (2) from hub (14).

A balanced plant for maximum production. All

(2) Delfate tire air pressure and remove tire (3)

rock crushing plants are designed from feed to

from wheel (TM 9-1870-1).

(3) Remove bolt (5) and remove hub cap (7) from

delivery for a balanced production ratio.

hub (14).

Conveyors, screens, the primary and

(4) Remove outer spindle nut (9) and inner spindle

secondary crusher, are of the correct size to

nut (11) from axle.

handle the anticipated tonnages under most

(5) Remove the brake drum (12).

crushing conditions encountered, keep in

(6) Remove hub studs (13) and remove the hub

mind that correct crusher settings and

(14).

selection of screen wire are all in vain if the

(7) Remove the inner and outer cone bearings (15

plant is not properly operated and maintained.

and 18) from hub (14).

(8) Remove nut (20), washer (21) and bolt (22).

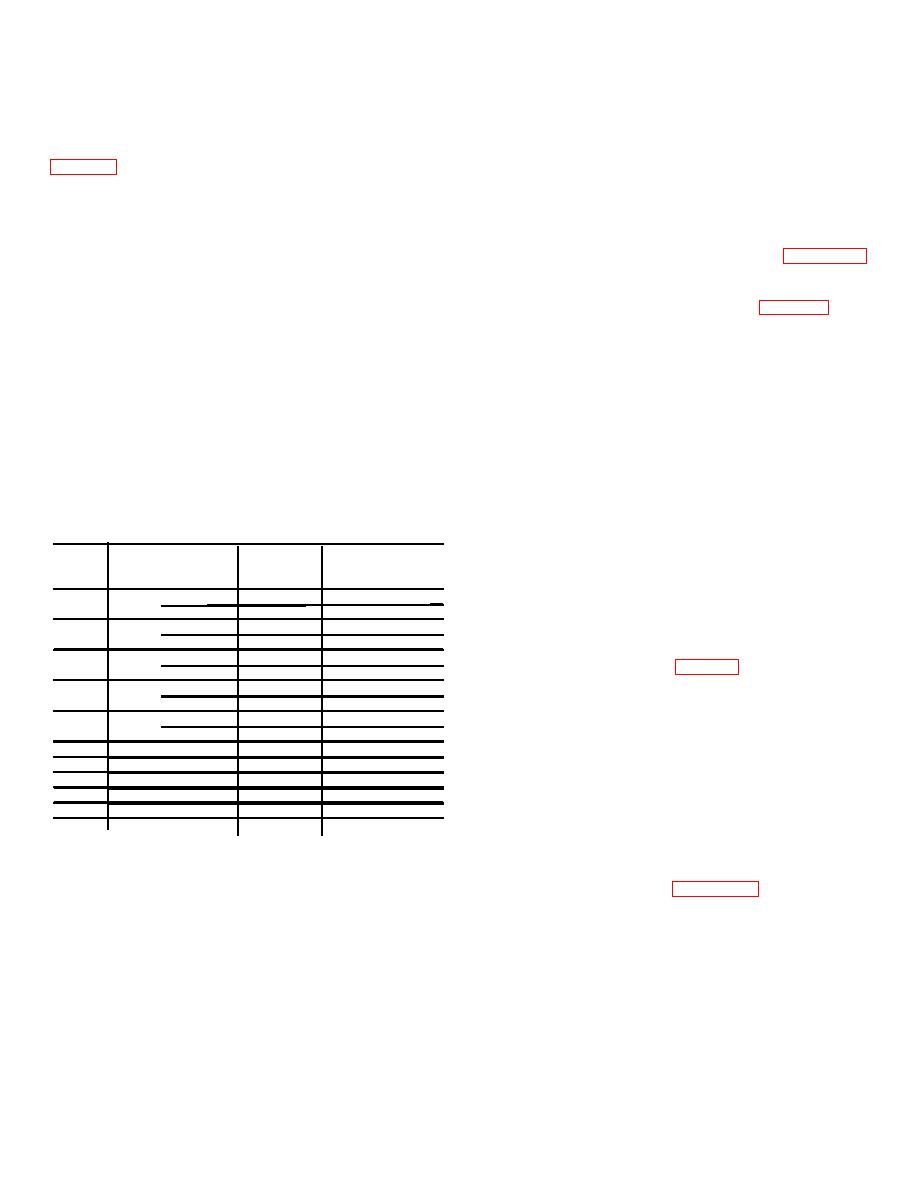

Table 4-3. Recommended Feed Size (Note 1)

(9) Remove slack adjuster assembly (25) and

Two Smooth

One smooth

remove the brake assembly (24).

crusher

See

Shells

one corrugated

(10) Remove screw (25) and remove dust shield

settine

note 2

24" roll

24" roll shell

(26) from brake assembly.

Recommended

5/8"

1/4"

Maximum Particle

7/8"

(11) Disconnect rod assembly and remove the air

Recommended

3/4"

brake chamber assembly (27).

3/8"

Maximum Particle

7/8"

c. Inspection.

Recommended

1"

(1) Inspect the tire (3, fig. 4-72) for excessive wear

1/2"

Maximum Particle

1-1/8"

or cuts. Replace a defective tire (TM 9-1870-1).

Recommended

1-1/8"

(2) Inspect the wheel (2) for damage.

5/8"

Maximum Particle

1-1/4"

(3) Inspect the brake drum (12) for cracks and

Recommended

1-1/4"

2"

scoring.

3/4"

Maximum Particle

1-3/8"

2-3/16"

7/8"

Recommended

1-1/2"

2-3/8"

(4) Inspect the bearings (15 and 18) for excessive

1"

Recommended

1-5/8"

2-9/16"

wear and inspect the bearing cups (16 and 19) for scoring

1-1/4"

Recommended

1-7/8"

3"

and pitting.

1-1/2"

Recommended

2-1/8"

3-3/8"

(5) Inspect the slack adjuster (23) and air chamber

1-3/4"

Recommended

2-3/8"

2-13/16"

(27) for damage and proper operation.

NOTE 1--Based on regular shaped particles with relatively smooth

(6) Inspect brake assembly for excessive wear.

surfaces. Irregular shaped particles and/or particles with relatively

(7) Inspect all hardware for damage and replace

rough surfaces, permit slightly larger feed

all defective parts.

NOTE 2-Recommetded particle sizes are within the prescribed

d. Installation. Refer to figure 4-79 and reassemble

reduction ratio. Maximum particle sizes are the permissible

and install the brake assembly, tire and wheel in the

occasional oversize particles that will be gripped under average

reverse order of removal.

conditions.

e. Adjustment. Adjust brakes as follows.

(1) Turn adjustment stud end of slack adjuster

4-72. Secondary Screening Unit, Wheel, Tire and

worm shaft until the brake drags.

Service Brakes

(2) Turn stud slowly in opposite direction until

a. General. The Secondary crushing and screening

brake is free of drag.

unit is equipped with service brakes on each wheel and

(3) Lower unit and road test for brake balance.

which are controlled by the air brake system of a prime

4-56