TM 5-3820-233-12/2

b. Adjustment. The elevating wheel trunion with the

4-63. Speed Reducer

adjustable idler wheel assembly is provided to align the

The Dodge Torque Arm speed reducers used on the

elevating wheel. When properly adjusted, the elevating

secondary crusher screening unit are located on the feed

wheel tire should ride in a central position on both

conveyor head shaft, the elevating wheel and

trunions. Before attempting to change the location of the

undercrusher conveyor countershaft and the side

trunions:

conveyor countershafts.

(1) Check plant lengthwise on the frame near the

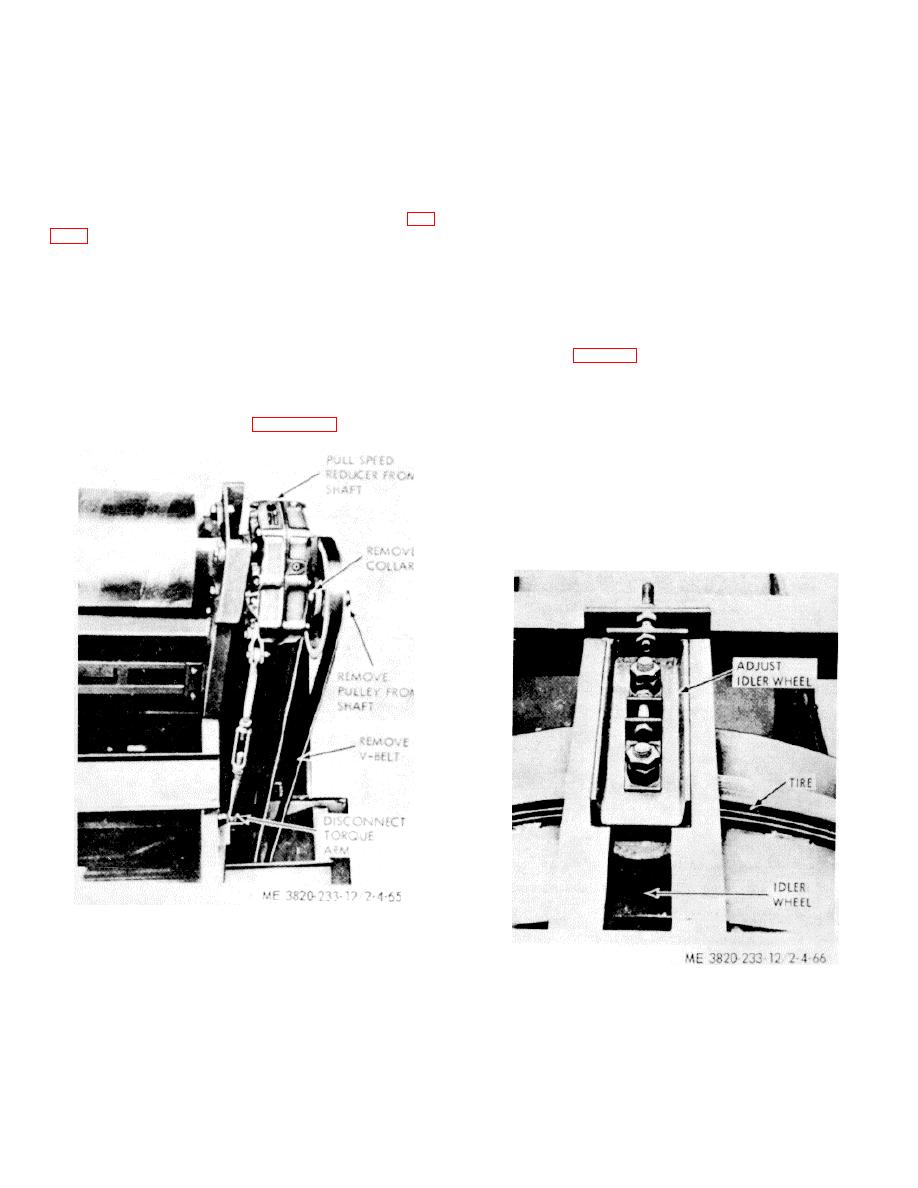

a. Removal.

trunions for level.

(1) Adjust torque arm to release belt tension (fig.

(2) Check distance between adjustable idler

wheels on top of elevating wheel and tire and adjust so

(2) Remove V-belts, pulley and bushing from

there is 1/32" clearance for tire to rotate freely between

shaft end.

idler wheels.

(3) Remove torque arm from support on frame.

c. Adjustment Procedure.

(4) Remove key from shaft and pull speed

(1) Loosen the trunions and visually locate the

reducer from countershaft.

elevating wheel with trunions centrally between hopper

b. Cleaning and Inspection.

side flashing (fig. 4-66).

(1) Inspect V-belts for cracks, damage and

(2) With crushing unit operating, and with

replace if necessary.

elevating wheel turning, notice on which side of right

(2) Inspect pulley, bushing and key for wear and

trunion the tire is riding the flange.

replace if necessary.

(3) Adjust the top of elevating wheel toward the

c. Installation. Refer to figure 4-65 and install in

opposite side from where tire is riding the trunion flange.

reverse order of removal.

(4) Check left trunion while elevating wheel is

turning. If the tire is riding the trunion flange, loosen and

slide trunion on shaft until contact between elevating

wheel and trunion flange is illuminated.

(5) At this point, the elevating wheel tire should

be adjusted properly and running in the center of

trunions.

Figure 4-65. Speed reducer, removal and installation.

4-64. Elevating Wheel

a. General. The rotating elevating wheel carries

Figure 4-66. Elevating wheel adjustment.

material from the undercrusher conveyor to the feed

conveyor. The overhead feed conveyor returns it to the

vibrating screen for sizing and scalping.