TM 5-3820-233-35/2

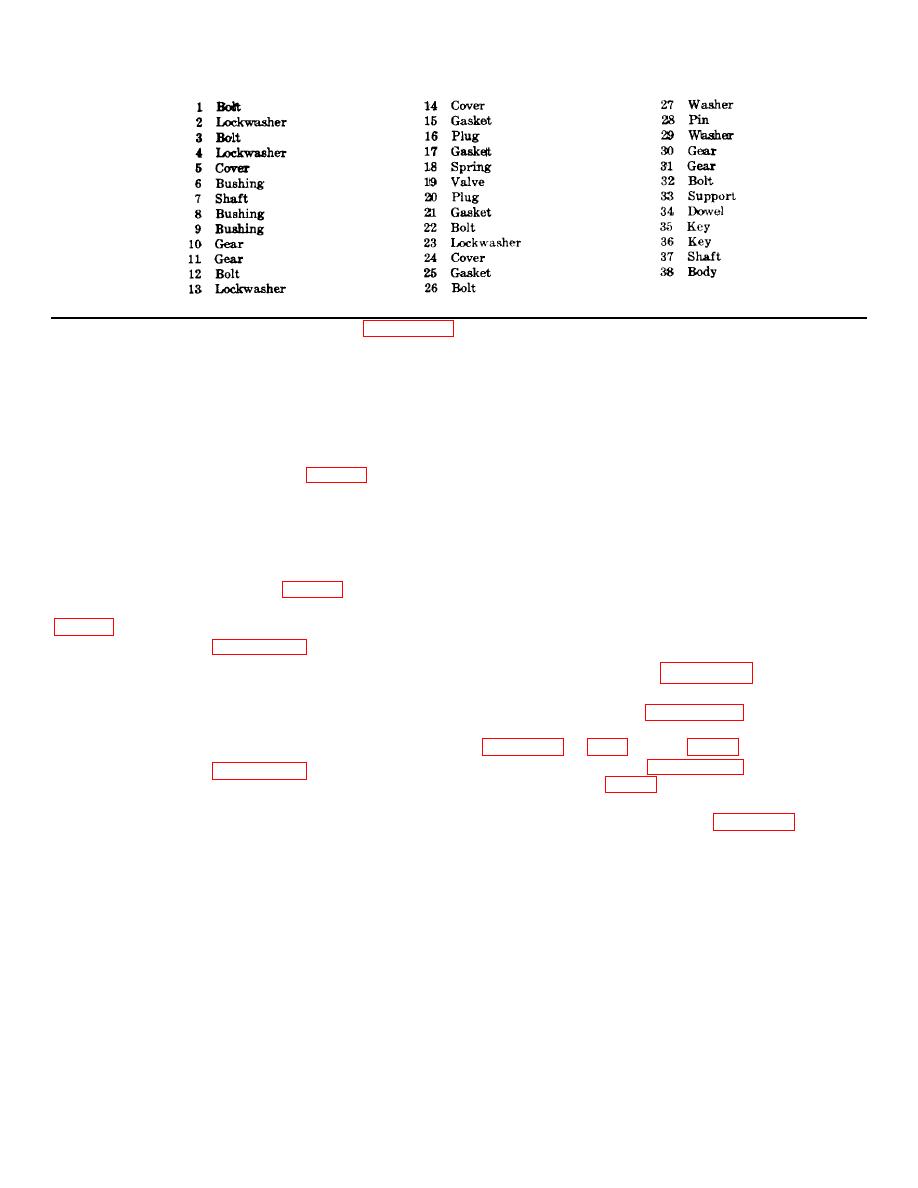

Figure 24-2 (1)-Continued

of the flywheel and is the mating gear for the starting

motor. The flywheel maintains even crankshaft speed

Caution:

and with the engine starter, provides a method of

Overheating to temperature above

400o F. will soften the gear.

starting the engine.

b. Removal

(3) Inspect flywheel housing for cracks and

other damage. Replace a damaged flywheel housing.

(1) Remove the power unit (para 23).

(2) Remove the muffler and air cleaner

Note.

(Operator's Manual).

(3) Remove the hoods, side panels, and tie

Remove all old gasket material from

rods (Operator's Manual).

the flywheel housing and end plate

(4) Remove the starter (Operator's Manual).

before installing a new gasket and

(5) Remove the oil pan (para 44).

the housing.

(6)

Remove the power takeoff assembly

e. Reassembly. Reassemble the flywheel and

(7) Refer to figure 27-1 and remove the

flywheel housing in the reverse of the numerical

removal.

sequence as illustrated on figure 27-3.

(8)

Remove

air

cleaner

brackets,

f. Installation

tachometer, overspeed governor, throttle control and

(1) Refer to figure 27-2 and install the

linkage from the flywheel housing. (Operator's Manual.)

flywheel housing. Follow the bolt tightening illustrations,

(9) Remove the two bolts securing the

engine lifter bracket to the cylinder head.

(2) Refer to figure 27-1 and install the

(10) Refer to figure 27-2 and remove the

flywheel. Refer to para 4 for torque data.

flywheel housing.

(3)

Use indicator and check the flywheel

c. Disassembly.

Disassemble the flywheel

housing concentricity as shown on figure 27-6.

housing in the numerical sequence as illustration on

(a) Adjust each dial indicator to read zero at the

figure 27-3.

twelve o'clock position. Then rotate the crankshaft one

d. Cleaning, Inspection, and Repair.

full revolution, taking readings at 45 intervals (8

(1) Clean all parts with an approved cleaning

readings each of the flywheel housing bore and bolting

solvent and dry thoroughly.

flange face). Stop and remove the wrench or cranking

(2) Inspect ring gear for broken or cracked

bar before recording each reading to ensure. Accuracy.

teeth. If replacement is necessary, remove gear from

The maximum total indicator reading must not exceed

flywheel with a blunt chisel. Install a new ring gear by

.013 inch for either the bore or face.

heating to expand it and pressing it onto the flywheel.

(4) Remove the bolts holding the lifter

bracket to the flywheel housing. Install a new gasket to

the bracket, then alternately tighten the bracket to the

flywheel housing and bracket to cylinder head bolts, thus

drawing the

3-35