TM 5-3820-233-12/2

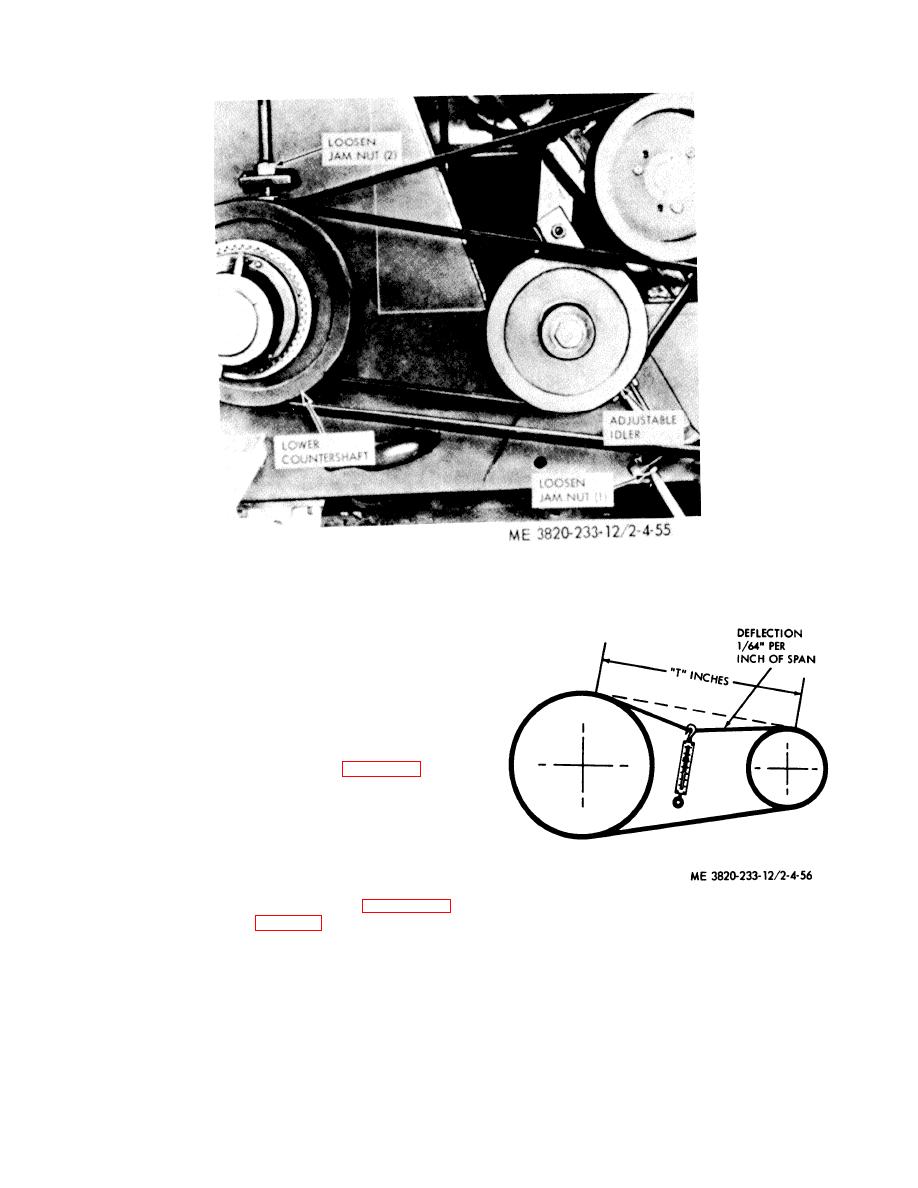

Figure 4-55. Lower countershaft to adjustable idler drive, V-belt adjustment.

i. Initial Belt Adjustment.

(1) Operate under load for 30 minutes, check and

tighten V-belts to remove initial stretch and seating of belts

in pulley. Then check tension again at the end of the first

hour of operation. After initial stretch has been relieved,

check every 50 or 60 hours of operation.

(2) Always check belts during extreme changes in

weather.

j. Correct Belt Tension. Refer to Table 3-3 and

determine belt tension.

(1) Measure shaft centers (in inches) dimension

"T".

(2) Multiply "T" by 1/64" which will give deflection

"S" dimension in sixty-fourths. Example: The deflection for a

100" span would be 100/64" or 1;'".

(3) Hook spring scale at center of belt span and

A. Smooth idler pulley.

read pounds required to deflect each belt "S" Figure 4-56.

V-belt adjustment. dimensions (fig. 4-56).

Figure 4-56. V-belt adjustment.

(4) Consult table for belt used. If spring scale reads

between the two figures shown, the belt is properly

4-58. Clutch

tensioned.

drive pulleys for the sand and rock side conveyors on the

secondary unit.

4-44